Today we’re diving in on our Century Arms VSKA review to let you know what we think about this popular AK model from Century Arms.

Introduction

One of the more interesting aspects of the VSKA that may be considered good or bad- depending on who you ask- is Century Arm’s decision to use S7 tool steel for certain core components like the carrier and front trunnion.

S7 tool steel is touted as having higher tensile strength and yield strength compared to Carpenter 158- which is the Mil-Spec bolt steel used in AR-15s- but has never been used in AK-47s- to our knowledge.

Most European Bloc countries forge the core components of their AKs out of 4130 and 4140, which are moderately hardenable, low-alloy, low-carbon chrome-moly steels.

4140 is often referred to as “ordnance grade” steel in the firearms industry and is used to make all kinds of parts due to its relatively low weight-to-strength ratio (amongst other desirable qualities such as ease of machinability).

It costs less than S7 tool steel and is easier to machine and forge, thus making it the go-to steel for firearms manufacturers at large.

The bolt Century Arms made for the VSKA is machined from 4140 carburized steel, which adds a layer of case-hardening to increase the surface hardness improving wear and corrosion resistance.

The front trunnion and bolt carrier are machined out of S7 tool steel from a forged billet, so they paid more for the S7 tool steel but saved money from machining billets rather than having them forged like a proper AK.

It’s understandable though since the initial costs involved in buying machinery to forge parts are enormous and not many factories exist that have these capabilities.

4150 chrome-moly steel, (the same steel used to make most AR-15 barrels), is used to make the VSKA barrel and is nitrided instead of chrome-lined, which is a bummer to AK purists.

This is a common (though less popular) choice that improves accuracy but is less durable (and is subject to corrosion if you use corrosive primers and fail to clean the barrel afterward).

The former Soviet Union had these forging operations in place at the Izhevsk plant since WWII and supplied other Com Bloc countries with the same capabilities to produce their own AK rifles using Russian tools and specifications- with much gratitude, I’m sure!

That being said, forging is technically cheaper for them to do since the equipment is already in place- even though it would be a much more expensive operation in the Western world without the equipment to start with.

What Century Arms does have access to is state-of-the-art automated CNC machinery that less developed countries could only dream of owning.

With this high-tech equipment, Century Arms can quickly make many types of parts from billets of aluminum, chrome-moly, and stainless steel.

So, it stands to reason that Century Arms would choose to make bolts, carriers, and trunnions (and other parts) for the VSKA out of billet as well as castings less vital parts.

This, in and of itself, is not an issue… but, more importantly, is the question of proper heat treatments.

The tensile strength of S7 steel in its natural “unhardened and unnaturalized” state is 2030 MPa, while its yield strength is 1520 MPa.

When hardened to a Rockwell hardness of 46HRC, it loses about 25% of its rated strength but prevents embrittlement under high-speed impacts and high-heat exposure.

From our perspective, so long as the heat treatment of those S7 front trunnions is done properly, this tool steel should hold up to normal wear and tear- no problem.

It’s true, that forging produces a more uniform and tighter grain structure that flows in the direction that the part takes shape, but billet machined parts can be quite durable when heat treated properly.

The common low-alloy steel used to make AK-47 bolts is high in durability, and shock resistance, but is not particularly “hard” in its heat treatment.

During the case-hardening stage, most of its hardness is derived from surface *carburization while the core of the steel remains softer to avoid becoming too brittle.

*Note: Carburizing is a long-established surface treatment method that adds a thin, yet hard, layer to the metal by infusing an external carbon source into the crystalline structure of the base metal (typically used on low-carbon steels) which aids in lubricity and increases wear resistance as well as helping to prevent corrosion.

The relatively simple bolt design and thicker locking lugs on the AK-47 lend themselves to being more durable and the lower pressures of the 7.62×39 cartridge don’t require the extra strength S7 tool steel would provide.

Looking for a good deal on a slightly used VSKA? Guns.com has several VSKA AK-47 rifles for sale in various conditions from new to used. You can find a great selection of VSKA AKs here: VSKA AK-47s

Who Makes The VSKA?

The VSKA (pronounced Vis-Kuh) is short for “Vermont Stamped Kalashnikov” and is a relative newcomer to the AK market getting its start in 2019.

Made entirely in the USA by Century Arms, this is one of the three most commonly made-in-the-US AKs available today.

They had a rocky start with various QC issues, especially at a press launch event where it pretty much failed miserably and blew up.

Their C39 V1 & V2 as well as their RAS47 models were plagued with QC issues and stories of cracked trunnions and other failures.

Fortunately, the VSKAs made today seem to have achieved decent reliability with a few caveats that we’ll uncover in the QC section.

VSKA Specifications:

- Barrel Chrome-moly 4150 Steel

- Front Trunnion Machined S7 Tool Steel Plate

- Bolt Carburized 4140 Steel

- Receiver 1/16” Stamped Steel

- Bolt Carrier S7 Steel

- Sights Standard AKM

- Caliber 7.62 x 39mm

- Stock American Maple

- Feed Ramp S7 Steel

- Trigger Century Arms RAK-1

- Finish Manganese phosphate

VSKA Quality Control Issues

Here is a list of all known quality control issues we’ve come across in our research:

- The use of billet-machined S7 tool steel instead of hammer-forged parts seems to have been improved in current production models

- Because of the steels used and how they’re manufactured, premature wear on load-bearing parts is increased and results in a less durable rifle compared to the others but time will tell if they fixed these problems.

- Standard 4150 chrome-moly barrel may be accurate but not as tough as cold-hammer-forged, chrome-lined barrels

- Loose-fitting upper handguards are common but haven’t been confirmed on current production models

- Though it has survived a few 5,000-round tests, it has shown uncharacteristic wear patterns that should be concerning to those who plan to shoot your rifle more than 5,000 rounds. Again, this was true on earlier models but more tests need to be performed on newer “improved” batches

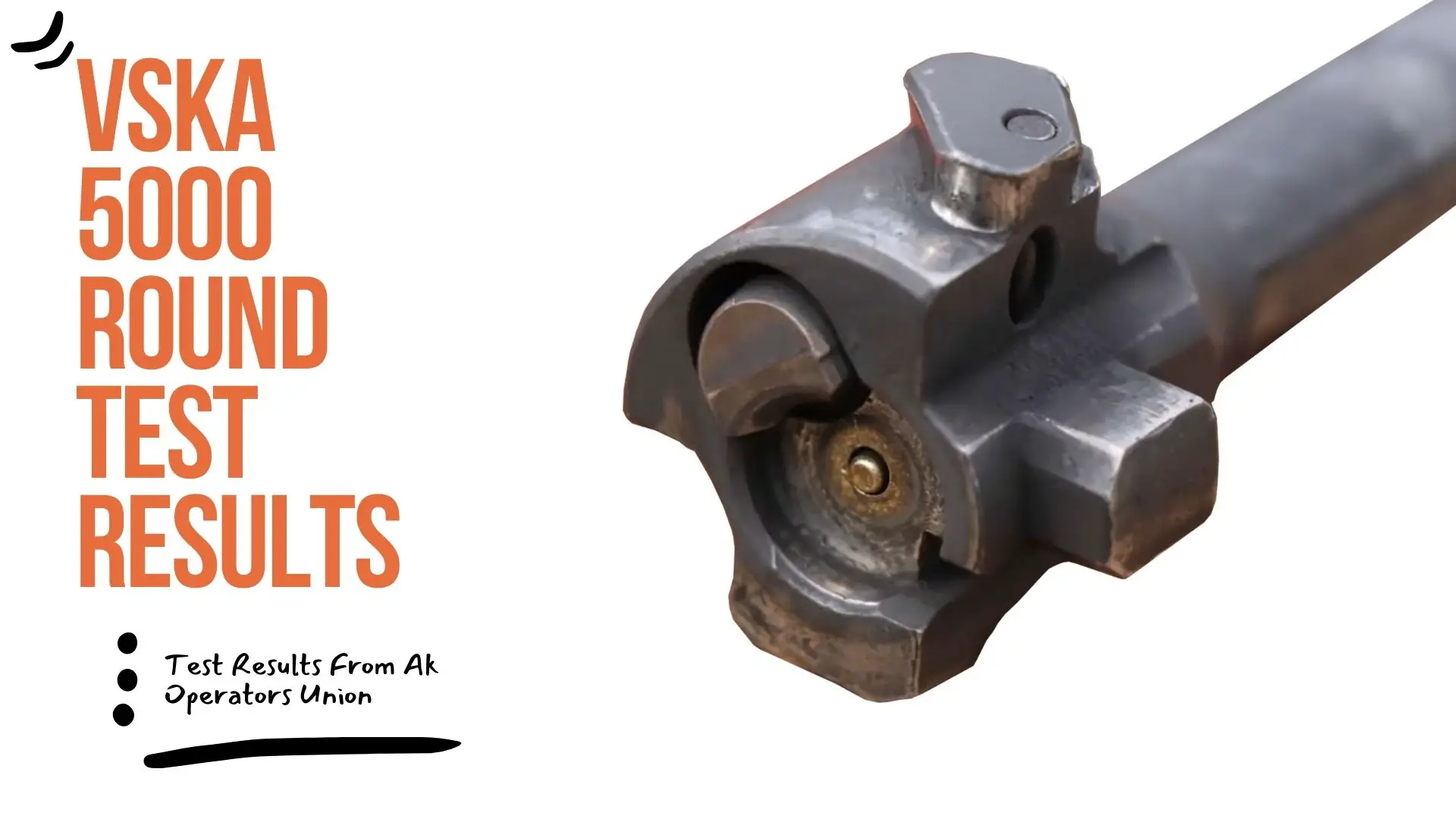

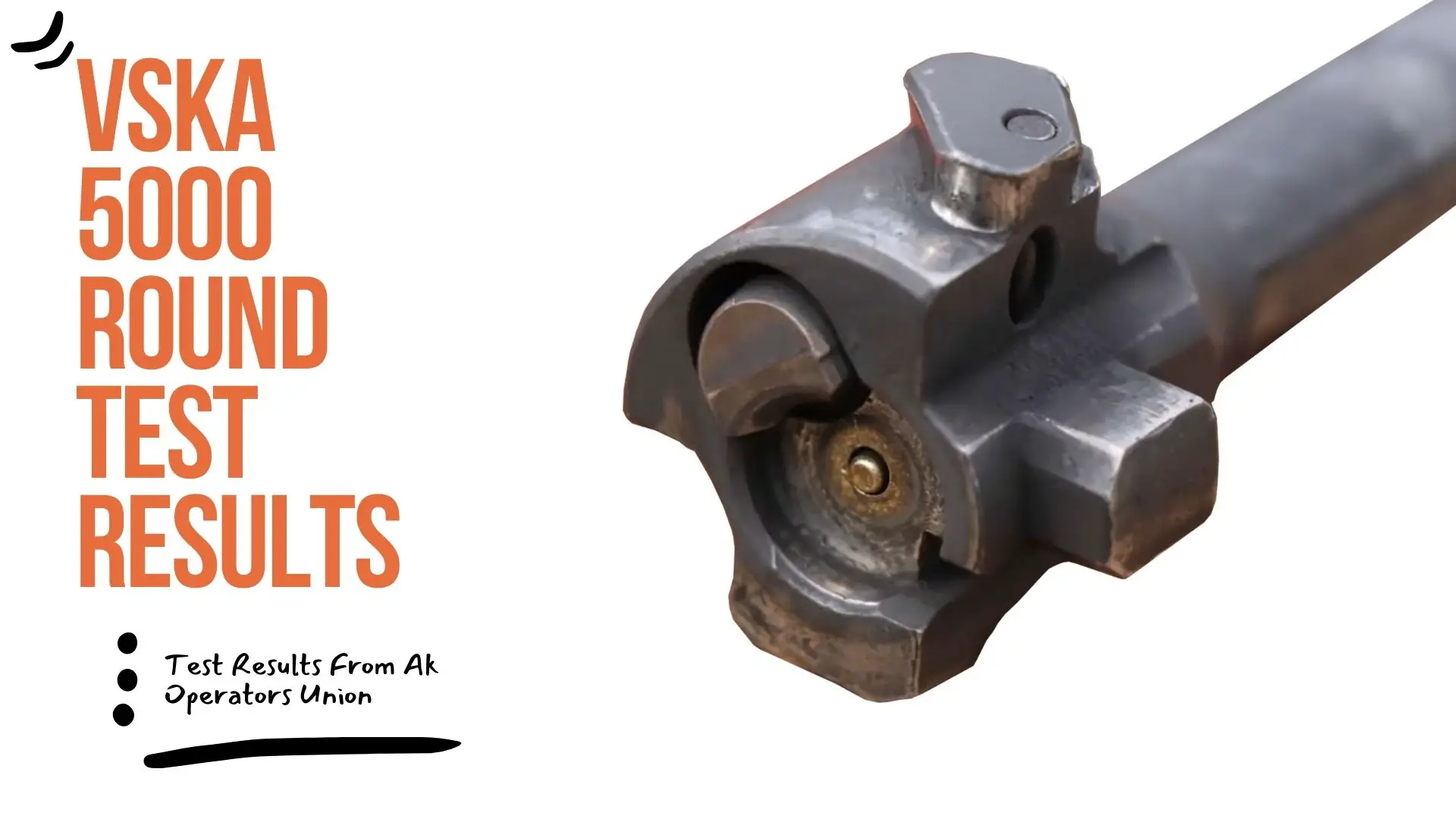

Century Arms VSKA Durability Test

Although the VSKA has its flaws, it seems to be constructed sufficiently to endure the average usage expected by most individuals.

In case you happen to be among the fortunate few who can afford to shoot thousands of rounds annually with your VSKA, the performance of this AK after firing 5,000 rounds cannot be guaranteed.

However, judging by the wear pattern on the bolt and trunnion, it is plausible to believe that it can potentially withstand at least 10,000 rounds if not more.

S7 tool steel is a strong steel alloy if heat-treated properly, and we’ve seen it used on high-end AR-15 bolts if that makes you feel better.

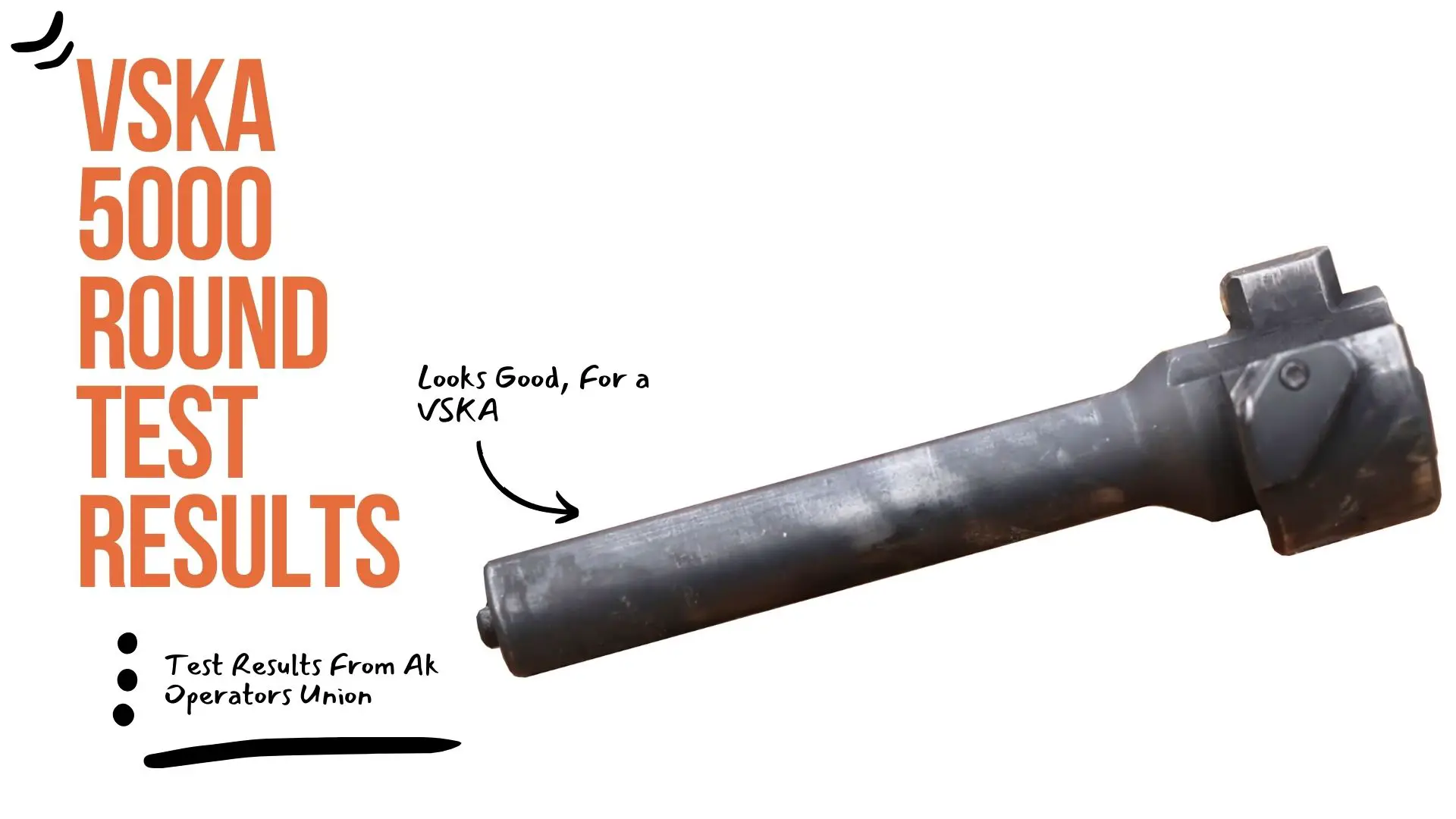

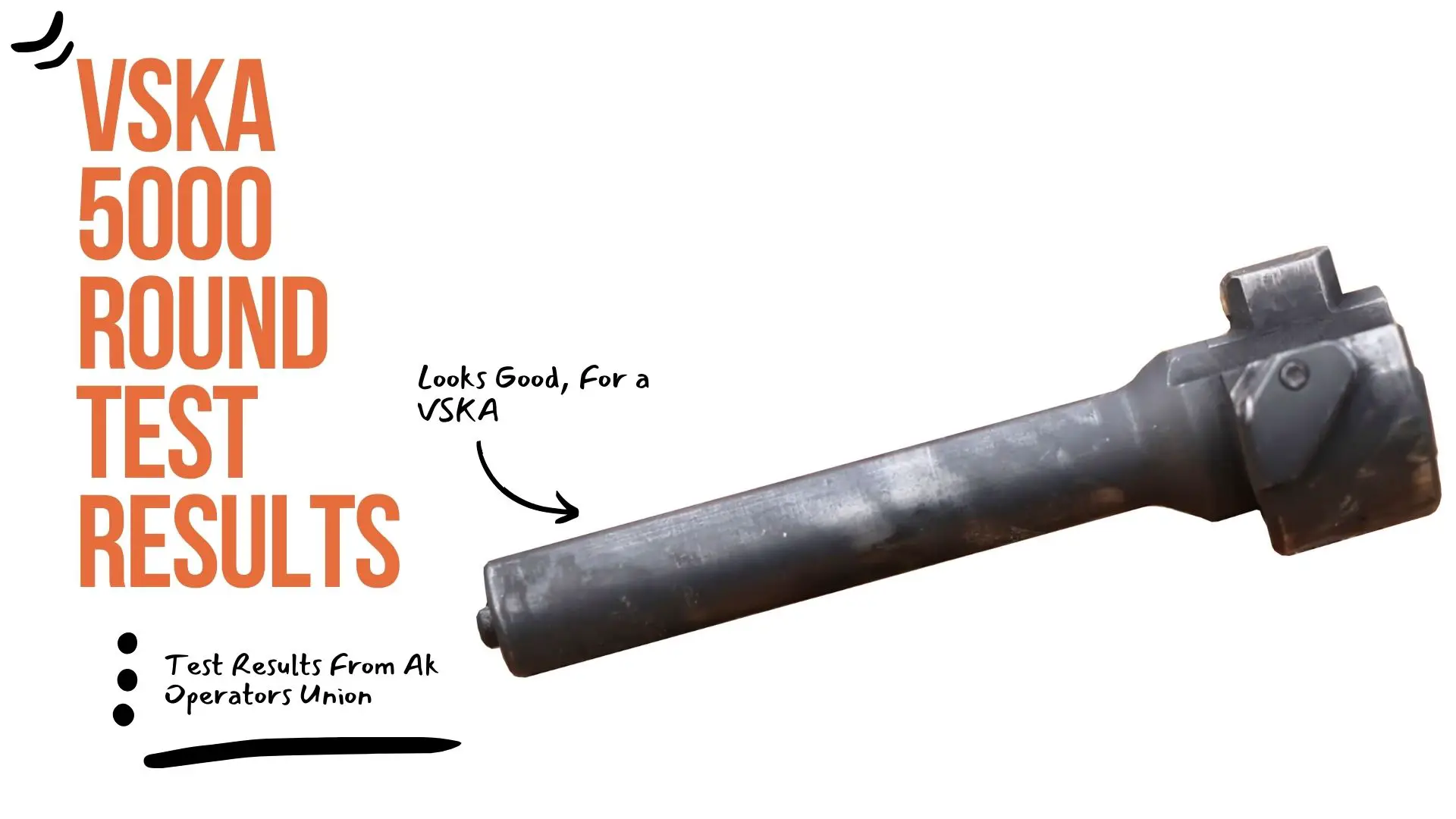

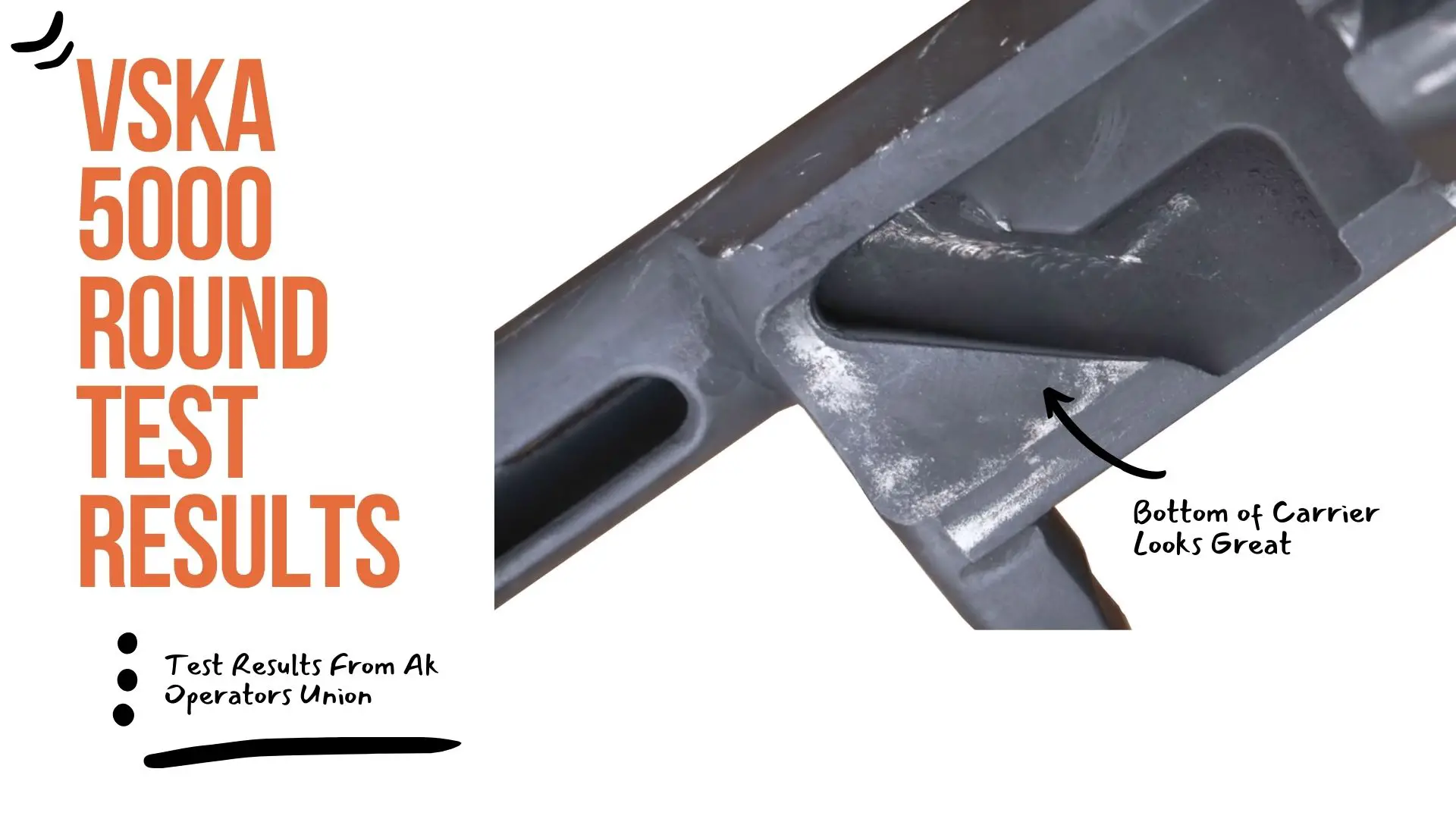

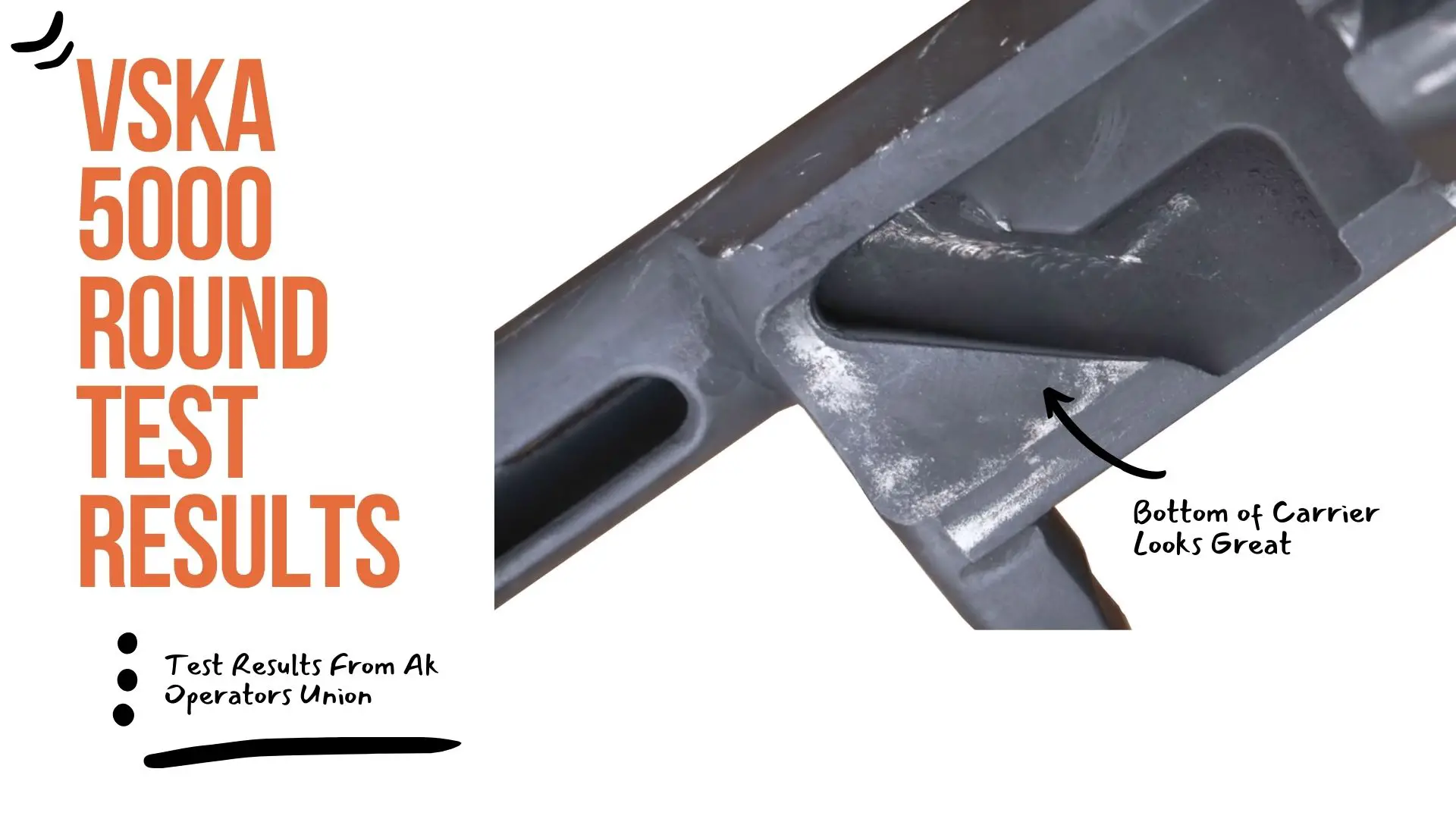

The wear pattern on the VSKA bolt and trunnion suggests that it was heat-treated well enough but the question remains; is the heat treatment consistent from VSKA to VSKA?

The only way to know for sure is to test a few from current and past productions with a hardness tester.

If it’s any consolation, we haven’t exactly seen a lot of complaints of VSKA AKs failing in the present so perhaps they have been doing things right, or at least “good enough”.

Perhaps nobody can afford to put 5,000 rounds through one to find out is more likely, but only time will tell! Here’s our favorite Polish-American Rob Skit putting the VSKA through its paces:

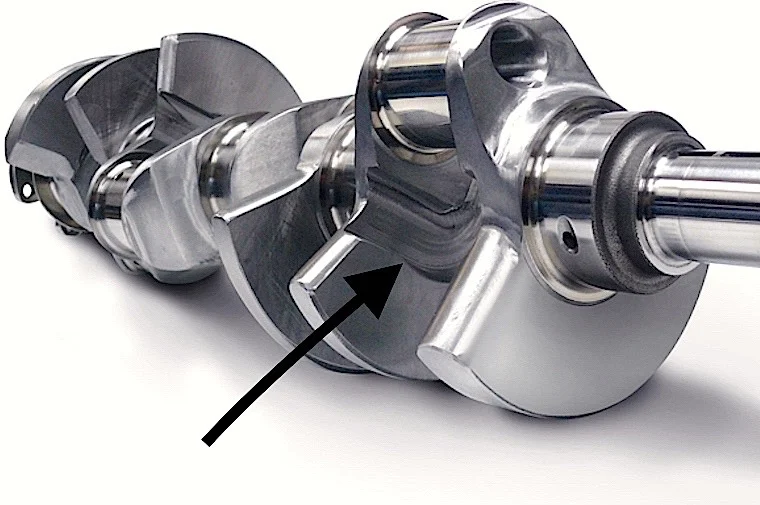

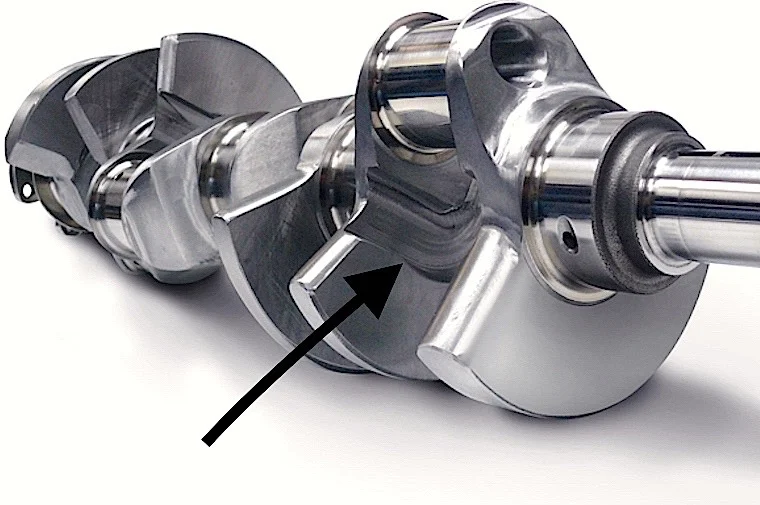

Here are the pictures of the wear patterns on the contact surfaces of the bolt, trunnion, and carrier.

Are these consistent with what Century Arms is currently producing? It’s impossible to say without further testing of newer models but at least the one that was tested survived, so there’s that.

Final Conclusions on the Century Arms VSKA

The Century Arms VSKA is probably one of their best efforts at producing a fairly decent AK-47 but is it worth the asking price?

I’d say if you already bought one, don’t beat yourself up too much over it, but if you haven’t then I’d say you’d be better served by saving up a bit more to buy a proven design like the Zastava or WASR-10.

They don’t even cost that much more and use all forged parts! The VSKA isn’t terrible though and even looks the part, even if it’s skin deep.

That’s all folks! I hope you gained some useful information to help you make an informed decision when buying your next (or first) AK.

If you already own a VSKA, feel free to leave a comment below and tell us about your experience owning one of these American-made AKs.

Many thanks for posting this, It?s just what I was researching for on bing. I?d so much relatively hear opinions from a person, slightly than an organization internet page, that?s why I like blogs so significantly. Many thanks!

Thanks man 👍

It’s exhausting to seek out educated people on this matter, but you sound like you realize what you’re speaking about! Thanks

Recently purchased a vska in the weathered laminate furniture. Have only run just over 100 rds. through so far. Some slow, some rapid fire. Rifle performed flawlessly. Time will tell, but I feel that unless you’re running thousands of rounds a year (who can afford that?) It’s likely sufficient for most people’s needs.

I totally agree with you on that point. I think most of the hate is based on past performance failures but is not really warranted now. Also, people love to LARP and imagine only having one AK that would take them through the apocalypse in one piece. Whether they’d outlive their AK is doubtful in that doomsday scenario, lol. As far as ammo costs, yea hardly anyone can afford to find out if their AK is indeed “bulletproof” (as much as I’d love to find out- it ain’t happening anytime soon!)

Just one more thing… if you’re only going to be using it as a range toy then 100 rnds without a malfunction is fine. If you’re thinking about potentially using it for home defense (most ppl wouldn’t) then I’d put at least 500 down range before trusting it fully. It usually takes between 500-1000+ rnds to expose any potential failure points in the heat treatment of key components.

I have one built in 2021 with about 1100 rounds fired through it now. Wear looks similar to other used aks ive inspected. Have been watching it closely. It has had zero malfunction so far including with garbage mags.

I have a VSKA that was manufactured on 7/11/2022; the overall QC and fit & finish are good, and it’s a solid rifle. I have just shy of 1,000 rounds through it and I’ve had zero issues with minimal wear.