This article is a helpful guide that will demonstrate and explain exactly what headspace is, why it’s important to know, and how to check it with the proper headspace gauges in the caliber of your firearm.

*Note: The focus of this article will be on HS gauges to determine if a firearm is safe to fire and not the HS gauges used specifically for reloading and resizing your brass.

Firearm Headspace Gauge Guide

Welcome to our firearm headspace gauge guide designed to help those new to the subject.

So, what exactly is headspace, and the gauges designed to measure it?

Internally, headspace is set by the cartridge design and is matched to the chamber diameter and length. Externally, headspace is measured between the face of the bolt and the rear of the chamber.

It’s important to have proper HS in a firearm because it allows for proper cartridge seating and function. If there is too much or too little headspace, malfunctions can and will occur.

That’s where headspace gauges come into the picture!

Now, let’s tackle some common questions we often come across regarding headspace to help further clarify their uses and benefits in different firearms.

How is headspace measured?

Well, several different gauges can be used to measure the headspace between the bolt face and chamber.

The two most common are the Go Gauge, No-Go Gauge, and the Field Gauge. A Go Gauge means how it sounds- you’re good to go!

A No-Go Gauge is a different story and many people falsely believe that if a firearm fails the No-Go Gauge it means the firearm is unsafe to fire. In a new rifle, the chamber will be in its best condition and so will the bolt.

If your rifle’s headspace is within specifications, the No-Go Gauge should not allow the bolt lugs to rotate and lock.

If it does, it’s only a matter of time before the rifle will open up these tolerances even further making it dangerous to fire.

If a rifle has seen a few thousand rounds down the barrel, however, it’s not uncommon for it to fail the No-Go Gauge.

This doesn’t necessarily mean that the rifle is unsafe to fire but simply means there is some wear on the lugs increasing the headspace. This is where the Field Gauge comes into play.

The Field Gauge is the final measure if a firearm is unsafe to fire. If the bolt closes on a Field Gauge, that weapon is unsafe to fire and will need a new bolt and possibly a new barrel if the chamber is also loose in its tolerances.

Above is a great video by Palmetto State Armory explaining this in more detail.

What Happens if There is Too Much or Too Little Headspace?

If there is too much headspace in a firearm, it can cause the ammunition to not fire correctly.

This is because there is too much room for the cartridge to move around, so when the firing pin hits the primer, the cartridge can move and cause misfiring.

If there is too little headspace in a firearm, it can also cause problems. Too little space can cause the ammunition to bind in the chamber, which will prevent it from firing.

Additionally, if there is too little space, it can damage or even break the gun and potentially cause severe injuries or death.

Is 7.62 x39 The Same as 7.62 NATO?

The Winchester NATO bolt-action rifle, sharpshooter rifle, and squad machine gun round is 7.62×51. It features a longer casing and heavier bullets, as well as more propellant.

| Cartridge: | 7.62×39 | 7.62×51 | Differences |

| Used By: | Communists Countries | Democratic Countries | Obvious |

| Case Length: | 39mm | 51mm | 12mm |

| Bullet Weight: | 123gr | 147gr | 24 grains |

| Muzzle Energy: | 1,607 ft-lbs | 2,586 fps | 979 ft-lbs |

| Muzzle Velocity: | 2,421 fps | 2,733 fps | 312 fps |

The casing also has grooves at the bottom. The casing length is indicated by the ’51’ symbol in millimeters.

The 7.62×39 cartridge is a light machine gun and assault rifle round.

Although the 7.62×39 cartridge is lighter and contains less propellant, it is better suited for rapid-fire magazine-fed weapons.

Is .223 and 5.56 the Same Headspace?

Although they are often mistakenly thought to be the same, the 5.56 NATO allows for a slightly larger HS than the .223 commercial caliber.

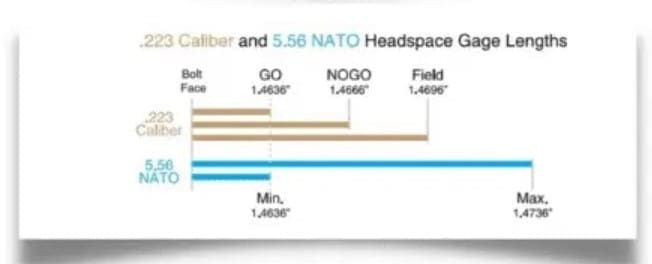

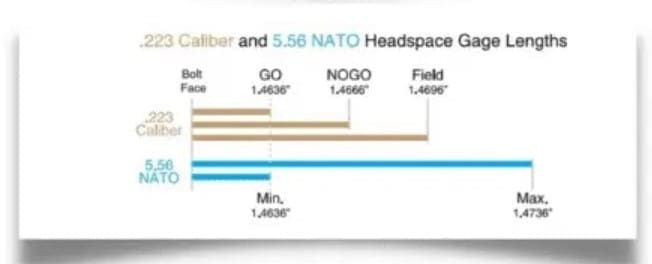

This diagram compares the gauge lengths regarding headspace for the .223 calibers and those for the 5.56 NATO.

You can fire SAAMI-compliant ammunition in a 5.56 NATO rifle barrel.

Because of the differences in throat lengths, firing .223 ammunition will not produce as precise a result as firing 5.56 NATO ammunition.

5.56 NATO ammunition is not safe to fire in a Remington rifle with .223 Remington-only barrel markings since it may contact the barrel rifling too soon, which can lead to pressure spikes that could cause damage.

Is 308 WIN and 7.62 NATO the Same Headspace?

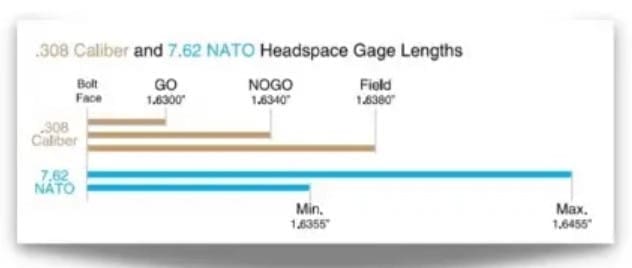

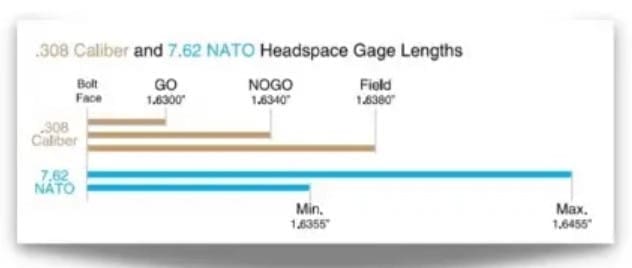

The headspace dimension of the 7.62 NATO chambering is larger than that of the 308 chamberings. This diagram compares the lengths of the tool gauges for the .308 WIN and those for the 7.62 NATO.

In the 1950s, the US Government developed the 7.62 NATO cartridge. It was lighter and shorter than the 30-06 and had better power and velocity. The 308 Winchester was soon introduced to the market by Winchester.

While the other dimensions of both cartridge cases are identical, there is one difference: The 7.62 NATO chambering has an additional headspace dimension than the 308 Chambering.

This means that the rifle chamber must be checked with the 7.62 NATO headspace gauge tool.

Headspace Gauges For 7.62X39

The AK-47 is the most talked-about rifle when it comes to headspace and the tools that measure headspace.

This is primarily due to the nature of their construction making it harder to find two AKs with identical headspace between the bolt and the head of the chamber.

These Go/No-Go, Field gauges are getting harder to find so pick some up while they last!

Here is our top headspace gauge set for .30 caliber 7.62X39 chambers:

#1 ZPV 7.62×39 Headspace Gauge Set (Go/No-Go)

When it comes to getting a high-quality set of go/no-go gauges, it doesn’t get much better than this set by ZPV.

“Used for a build. While using an actual live round will create a tighter tolerance than using the GO gauge, however its a good start. If your bolt can BARELY close with the GO gauge, you will have a nice tight tolerance. Triple check headspace with live rounds (firing pin removed) to verify amongst various brands of rounds.”

nperez

Features:

- The set includes a GO and a NO-GO gauge

- Manufactured to CIP specifications

- Tough Steel Construction For Years of Use

- Precision-machined

- Made by ZPV of Serbia

Headspace Gauges For 5.56 NATO

It’s much easier to achieve the appropriate headspace on the AR-15 platform when assembling a build from separate parts.

These tools for measuring headspace will ensure that your AR-15 build is within Colt’s specifications with the 5.56 NATO cartridge.

It’s always a good idea to have a set of Minimum and Maximum gauges on hand to verify headspace when switching to a new BCG (bolt carrier group) or before shooting an AR-15 that’s had tons of rounds through it, just to be on the safe side.

Here is our top headspace gauge set for .22 caliber 5.56x45mm NATO chambers:

#1 Forster NATO AR-15 Headspace Gauge Set

Forster is a solid brand in the headspace gauge market and offers this excellent NATO Min/Max set for AR-15 rifles.

“These seem to be decent gauges and the several guns I have built using them have not blown up in my face so, I would guess that they are fairly accurate. Finish seems to be decent although the labels and sizes written on them are kind of hard to make out. I just put a green and red stripe on them so I don’t get them mixed up.”

Duane

Features:

- 5.56 NATO CHAMBER HEADSPACE GAGE: The proper use of Headspace Gages is the most reliable way to test rifle chamber length. The 5.56 NATO maximum chambering requires a slightly longer headspace than the commercial 223 cal. Rem.

- GO/MINIMUM LENGTH: Corresponds to the minimum chamber dimensions. If a rifle closes on a GO gauge, the chamber will accept ammunition that is made to SAAMI maximum specifications. The GO gage is essential for checking a newly-reamed chamber to ensure a tight, accurate, and safe chamber that will accept SAAMI maximum ammo. NATO Minimum rifle chamber gauge check to see that the rifle will accept the longest (headspace dimension) NATO ammunition cases that are currently manufactured.

- MAXIMUM LENGTH: The Forster NATO Maximum rifle chamber gauge checks to see that the rifle does not have excessive headspace, which could lead to dangerous pressure problems. The NATO Maximum Headspace Gage measures 1.6455″

- PRECISION MACHINED: Manufactured from top-quality, hardened steel and precision ground to ANSI and SAAMI tolerances. Headspace tolerance ground to a very exacting ±.00015. Each Headspace Gage is thoroughly inspected with NIST-certified measurement tools to ensure the highest quality product.

- MEASURING MEANINGFUL HEADSPACE: Properly speaking, and for safety purposes, one measures “headspace” as the difference between the length of a standard cartridge, as represented by a gage, and the gun’s actual chamber length, when the head of the cartridge is flush against the bolt face.

The Different Types of Headspace Tools and What They Do

Firearm headspace and the tool gauges that measure it are devices used to measure the distance between the bolt face and the breach of a firearm.

This measurement is important because it ensures that cartridges will fit properly in the chamber and that the weapon is safe to fire.

Headspace tools can be either Go, No-Go, or Field gauges, depending on their purpose.

GO gauges are used to verify that a firearm’s headspace is within factory specifications. NO-GO gauges are used to ensure that a firearm cannot be fired if its headspace is too large.

Field gauges determine whether a firearm is within its maximum tolerances after it has been exposed to heat during firing.

By using these gauges, gunsmiths can ensure that firearms are properly assembled and that they will function safely.

When reloading ammunition, headspace gauging tools ensure that the cartridge is properly seated in the chamber and that the cartridge is not too long or too short.

When a round is chambered, the bolt face contacts the shoulder of the cartridge. This creates a datum point for measuring headspace.

If the cartridge is too long, it can cause problems such as case separation or pierced primers. If the cartridge is too short, it can cause failures to extract and/or failures to eject.

How to use headspace gauges

Gauge tools for measuring headspace are an important part of firearm maintenance and are used to check the chamber dimensions of a barrel.

As discussed previously, there are three types of headspace tool gauges: go, no-go, and field.

A go gauge is a piece of metal that is the same diameter as the chamber and will fit into the chamber when the barrel is in battery.

A no-go gauge is slightly larger than the chamber and will not fit into the chamber when the barrel is in battery.

To use a headspace gauge, first, remove the bolt from the rifle or open the breach. Then, insert either a go, no-go, or field gauge into the chamber.

If the go gauge fits into the chamber, then the headspace is considered to be within specification. If the no-go gauge fits into a cold chamber and the bolt fully closes, then you need to take steps to fix it.

The same is true if a field gauge fits into a hot chamber and the bolt fully closes.

Headspace gauge manufacturers

Gauges are tools that are used by firearms manufacturers to test both the potential safety and accuracy of firearms concerning headspace.

By using a headspace gauge, the manufacturer can quickly and accurately measure the distance between the face of the bolt and the rear of the chamber.

This measurement is then compared to the specifications for that particular firearm. If the measurement falls within the acceptable range, then the firearm is considered safe to shoot and will be more accurate.

If it does not fall within the range, then adjustments are made to bring it within spec.

There are many firearm gauge tool manufacturers, including Forster, Manson, Winchester, ZPV, Clymer, Hornady, and Pacific Tool and Gauge– to name some of the most commonly available brands.

Each of these companies offers a variety of headspace tools in different sizes and calibers. They also offer headspace tools and kits that include everything you need to properly measure headspace.

Final Thoughts

The purpose of this article is to provide you with some basic information on the use of headspace gauges as tools for improving safety and ensuring accuracy.

In short, a headspace gauge is an important tool for any shooter, as it allows you to measure the amount of space between the cartridge case and the chamber of the firearm.

By doing so, you can ensure that your rounds are being securely chambered and that your firearm is operating within its acceptable tolerances.

Thanks for the great post about headspace gauges. If have a set of go/no-go gauges with no markings, is there a way to determine the caliber/family? O.A.L. GO is 1.5920″ and NO-GO is 1.6025″.

I believe that’s a set for .40 caliber chambers.

Joe Coxe, Marc-Allen Coppock in the Conroe area. I enjoyed this writing. I have mostly been dabbling with .223/5.56 that I assemble from parts sold by various manufacturers. I use Forester Go,No-Go, Field gauges on barrels that I purchase. I just started to reload about a year ago, so I do use Lyman Case Length/ Headspace gages to set my sizing dies. Like I tell folks, I’m 72 going on 73 and I’d like to keep it that way. Yep, just turned 73 this week, the 13th.

To my point, I recently became interested in the 6.5 Grendel. I started out all wrong. I ordered a Diamondback barrel (type I) and a BCG from MidwayUSA (type 2). The Diamondback barrel was beautiful, however the gas port was canted out of alignment with the barrel extension by a 1/16 “. That was weird, it’s not the first time this has occurred. I started doing some research on the 1 & 2 and the bolt face depth differences, 0.125 vs 0.136. Anyway, I ordered an AR Stoner complete upper last week and I received it yesterday. I first stripped the bolt extractor, cleaned the chamber and checked the headspace on this 6.5 Grendel using Forester gages. Go Gage, it’s a Go. No-Go Gage, it’s a Go, Field Gage, it’s a No-Go. These Forester Gages are to SAMMI Specs when Bill Alexander first developed the 6.5 Grendel. I believe at that time they were using a 7.62 x 39 BCG with a bolt face depth of 0.125. I called Forester after I purchased these gages, asking what kind of results I would get on a Type2 bolt (0.136)? The guy I got hold of could have cared less and really was not interested in giving an opinion. He just said, we just make them (the gages) to SAMMI Specs. WOW!?! I was just curious, if I had just wasted $120 on three gages since most platforms are now using the Type 2 (0.136) bolt.

Any ideas where can I could up with, at least, a No-Go gage for the Type 2 to double check barrels and BCG for compatibility?

Any thoughts? Thanks

Thanks for the question Marc (and happy B-Day!).

Your journey into reloading and assembling firearms, especially with the transition to 6.5 Grendel, highlights the intricacies and challenges that come with custom firearm assembly and reloading. The issue you encountered with the mismatch between the Diamondback barrel (Type I) and the BCG from MidwayUSA (Type 2) is a common pitfall due to the 6.5 Grendel’s unique evolution and the existence of two bolt face depths.

The difference in bolt face depths between Type 1 (0.125″) and Type 2 (0.136″) is significant, especially when it comes to headspacing and ensuring the reliability and safety of your firearm. Your experience with the Forester gauges and their response reflects a gap in the market for specific tools tailored to the nuances of the 6.5 Grendel, particularly for those working with the more common Type 2 bolt.

Finding a No-Go gauge specifically for the Type 2 bolt face depth can be challenging, as most gauging tools are made to SAMMI specs, which may not account for the variations within the 6.5 Grendel platform. Here are a few suggestions on how to proceed:

Contact Specialty Manufacturers: Some manufacturers might produce or custom-make a No-Go gauge for the Type 2 bolt face depth. It may be beneficial to reach out to companies that specialize in precision gauges and custom firearm tools. While Forester is a reputable brand, there are others in the market who might offer more specialized services or products.

Custom Gauge Creation: Consider contacting a gunsmith or a machine shop with the capability to manufacture custom tools. They might be able to create a No-Go gauge that meets your specific requirements for the Type 2 bolt face depth. This could be more expensive but would ensure you have the exact tool you need.

Online Forums and Communities: The firearm community is vast and knowledgeable. Posting in forums dedicated to reloading and custom rifle assembly, especially those with a focus on the 6.5 Grendel, might yield some valuable insights or sources for the gauge you need. Members might know specific suppliers or have personal solutions for similar situations.

Manufacturer Support: While your initial attempt with Forester didn’t provide the answers you were looking for, reaching out to other manufacturers of 6.5 Grendel barrels and BCGs might be helpful. They could have recommendations for gauging tools or even offer their own solutions for ensuring proper headspace with Type 2 bolts.

Gun Shows and Specialty Shops: Sometimes, hard-to-find tools can be sourced from gun shows or specialty firearm shops. Vendors at these events or locations may have more obscure items or be able to point you in the right direction.

Your diligence in ensuring the safety and proper assembly of your firearms is commendable, especially given the complexities of working with different standards within the same caliber.