So exactly how much abuse can an AK-47 take? How does 100k worth of auto fire down the barrel of a WASR-10 sound?

Let’s find out!

On 5/15/2015, a thread post about AK-47 abuse on the AR15.com forum was started and everyone who eagerly read or participated in the Q&A session learned a little more about how well the WASR can actually hold up to the abuse of full-auto fire.

Thanks to the contributions of a poster that goes by “HendersonDefense” (aka V/R Ron), we found out more than we could have ever known with our limited scope of use on our AK-47s that are lucky to see 5,000 rounds down their barrels.

Now we can finally know, unequivocally, that some AK-47s, like the WASR-10, are damn near indestructible…especially when it comes to what most would consider “real-world use”.

So, if our end-of-the-world fantasies ever come true, we’ll be killing hordes of mindless zombies with our trusty battle-tested WASR-10s, blasting a pathway towards the nearest safe house, and live to LARP another day!

Every single aspect of these rifles would be stress-tested from the cold-hammer-forged barrels to the bolt carrier groups, to the fire control groups, to the receivers and trunnions… not to mention those all-important rivets!

Firing a stupendously ludicrous round count we lowly mortals could only dream about, this was the best real-world data we could ever hope to find! And, thanks to Ron @ Battlefield Vegas, we’ve laid it all out for you in an easy-to-digest format.

The visual of that giant container of spent Wolf steel 7.56×39 casings filled up to the top was jaw-dropping to behold. Of course, there were some other calibers mixed in but the vast majority were AK rounds.

We came to learn that the frowned upon WASR is often joked about as being assembled “by a monkey with a wrench”, ugly as they may be, these AK 47 rifles are made from Beskar steel!

This Battlefield Vegas AK post is well known in AK circles but most are unaware of its treasure-trove of data. This 11-page forum post consisting of over 11,000 words is frequently talked about and quoted in forum posts from a myriad of sources on the interwebs.

Oftentimes, the information is not correctly remembered- or sometimes bent to favor some shmuck’s fragile ego. Hell, I remember hearing about this magical post for the first time from a debate in a YouTube comment section.

Maybe that’s how you discovered it too? Maybe you know because you actually went shooting at Battlefield Vegas and talked about it there… but I digress!

At the time, I didn’t even know where to find this mythical AK-47 mana they spoke of. Our goal for this article is to break down this massive 11-page post into easily quotable (and organized) information so you can prove you were right all along- and why they are so, so wrong!

Oh, and did I mention we included all of the original photos from the exchange? Yep, you’re welcome!

Distilling The Aptly Titled “AK Abuse” Forum Mega-Post For Your Consumption.

In Ron’s Words:

I’ve read a couple of threads about “abusing” AK’s and I haven’t seen anything that’s “real world” abuse. At our range, we treat each weapon the best we can but the sheer volume of rounds we put through our full-auto AK’s (and all other weapons) unfortunately leaves them cracked, split, bulged, and kaboom. Each weapon is headspaced at every cleaning, documenting in its own maintenance log the headspace and what or if any parts were replaced.

“The one thing I can say about the AKs is that they hold up MUCH BETTER than the RPD’s. I thought for sure that RPD’s would last so much longer because of the milled receivers but the receivers only last about half the life (if that) of a Romanian WASR.”

“This is about 30 days (at most) of steel casing and approximately 80% of it is from AK usage. The other brass is from RPD’s or PKM’s.

Q: The stamped receivers hold up better than the milled ones? Interesting. Impressive steel collection

A: Well, to be fair, the Century milled C39 receivers have lasted but all of the barrels lost their headspace. They were on the line for quite some time but now we have three waiting to be repaired sitting in a weapons rack. I initially was suspect of the Century milled AK receivers but they have lasted. The barrels are from the initial release of C39’s before chrome-lining was offered. I haven’t paid much attention to the choices now but I did see they offer them with chrome-lined barrels now.

Q: What part of the receiver wears out? Seems like that would be the last thing to wear out, milled or stamped.

A: “Every single stamped receiver has suffered from a cracked trunnion. This includes Saiga, Arsenal (Bulgarian), Norinco (Chinese), Arsenal (Russian stamped), WASR, Hungarian, Polish (vintage kits), Yugo (vintage and PAP-series), and new Polish (from Royal Tiger imports).”

Q: What variants do you test? Can you rate them?

A: We have every type of AK available to shoot except for Cuban, Vietnamese, or North Korean.

“US (Century), Bulgarian, and Chinese milled receivers have yet to fail.”

Stamped receivers split at the angle of the upper rail and the sidewall. N-PAPs have literally cracked in have perpendicular the length of the rifle. The receivers cracked just posterior the front trunnion (between the center bushing and the trunnion).

Q: Who makes the best barrels? By best I mean longest lasting.

A: We have yet to shoot out a factory WASR barrel. The barrels on three of our C39’s started to keyhole and were pulled. We have WASR’s on the line that has last OVER two and half years and the barrels are NOT shot out and they continue to run. We installed new bolts to bring headspace back up but they keep running.

The Draco-Cs that we converted over three years ago is finally down to the last unit. Most have cracked trunnions but one of the barrels right past the gas block literally cracked off. The portion of the barrel with the threads cracked right off while shooting. I will see if I still have pics on my phone. This may sound crazy but it’s fair to say that they finally suffer a catastrophic failure (cracked trunion) at 80,000-100,000 rounds. Also, we have WASR’s that have suffered a catastrophic failure and we just pull out the old trunion and barrel, grab one from a parts kit, re-rivet, re-barrel and get them up and running.

The AK is the most reliable but after seeing how many have broken over the last two and half years on the range, it’s not the indestructible weapon everybody talks about (and I always thought it was). What makes it reliable is its simplicity. My guys clean/service 4-5 AKs for every M4 or MP5.

“The Uzi’s just as simple but you wouldn’t believe how often components of the top cover fail. “

We purchased 75 kits about a year ago and we have gone through so many top covers. We will lose an extractor here and there but not often enough to complain about.

Q: After how many rounds do they usually go to shit? Which FA weapon is typically the most reliable over time and round count? What is the most popular rental?

A: The three most popular rentals are the AK47, MP5 and Uzi. People want to shoot the AK because they are so popular in the news and movies but then want to shoot the Uzi because of the name and then finally shoot the MP5 because it’s so smooth and has no recoil.

Q: You said the milled RPD guns failed before the stamped guns earlier.

A: I meant the milled RPD’s failed before the stamped AKs. I always expected the RPD to be such a stronger weapon considering it’s the same caliber as the AK and much thicker receiver.

Q: I would like to know more about how the trunnions typically crack if there is a pattern to it. I used to read stories about early Type 2/3 milled receivers sometimes cracking locking lugs due to fatigue, which was supposed to be an improvement that was a result of the stamped receiver flex and isolation of the breech block… Supposedly heat treating on those receivers was poor. Good to know the modern production receivers don’t have that problem.

When you say the barrels are losing headspace, is this due to wear on trunnion/bolt locking contact surfaces, or is the barrel gradually egging the barrel pin channel with use and allowing it to move? High round count issues are always interesting, especially with this thread going on that basically claims most AKs will fall apart in a couple of thousand rounds.

A: I am not the expert when it comes to issues of headspace but I believe it’s due to wear on the bolt locking surfaces and the barrel face. When the headspace gets towards the acceptable level, the armorers will swap bolts until they get good headspace. The milled C39’s that have excessive headspace couldn’t be “fixed” by installing new bolts. They are going to try and press the barrel in slightly (and I mean the armorers pressing it 1000th’s of an inch) and oversizing the barrel pin on one C39 and see what happens. V/R Ron

You might be interested to know that the man who started the great AFRcom GD AKs-shoot-themselves-apart-myth once belonged to a different website that is devoted to AKs.

He posted pictures of indigenous people firing AKs. Those pictures included a Type 1, several type 2s, and AKMs. The “newest” weapon was a 74 … which had no finish. All were in working order.

I also note that no one in GD who claims that AKs shoot themselves apart has managed to capture a photo of even one broken weapon. I guess they move too fast when wounded. OTOH you might want to look at some credible data like the tests conducted by the Polish military with the “Tantal”. IIRC the test weapons lasted 15,000 to 20,000 shots – which included launching grenades.

Here are some picks of the failures that are pretty typical. I apologize for the pics but they are from my phone and it was just so we could show others in the shop what happened.

This is where the trunnions crack. The area of the locking lug will bulge right out when it cracks. The sheet metal never cracks or snaps, it just bends with the trunion.

You can see the crack running along the angle of the receiver bend for the top rail. This is pretty common on high-count receivers. We have just tig’ed them back up and they will continue to function properly.

Here’s the barrel that literally cracked off while firing. This is a Draco-C unit and I am sure it would still function but we can’t take any chances.

Q: Someone with more patience should start a running tally of parts breakage and approx round counts.

A: That’s something we’ve talked about in the shop. Some of the other guys have kept a box of all the broken parts that one would never expect to break. Slant brakes splitting in half, gas pistons snapping at the base where they screw into the carrier, spot welds failing on the lower rails, lugs shearing off the bolts, and carrier bodies cracking. As for AK-74’s, the thin bolt “stem” has cracked on various bolts and cracked trunnions.

Q: Have you tested Veprs? If so, how do they hold up?

A: We haven’t tested any VEPR’s. The only Russian AKs we have are some Saiga’s that I converted back to a military configuration about 3-4 years ago. We have customers from around the world come in and they ONLY WANT TO SHOOT A RUSSIAN Kalashnikov. They want to see the receiver and verify that it was made in Russia and they are happy as can be. The only reason we haven’t used VEPR’s is that the WASR’s have been so reliable there’s never been a reason to spend more money on the VEPR and then have to bring it back to a military configuration.

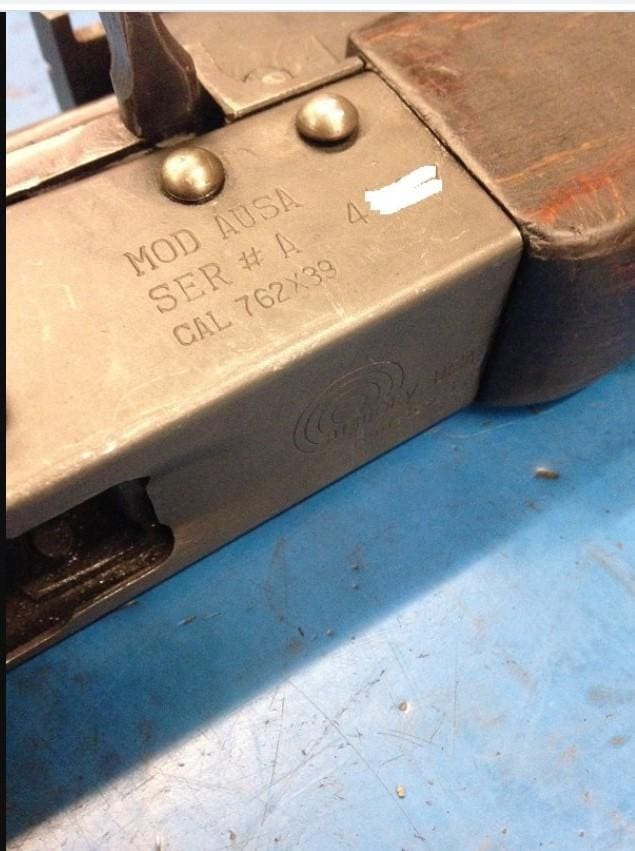

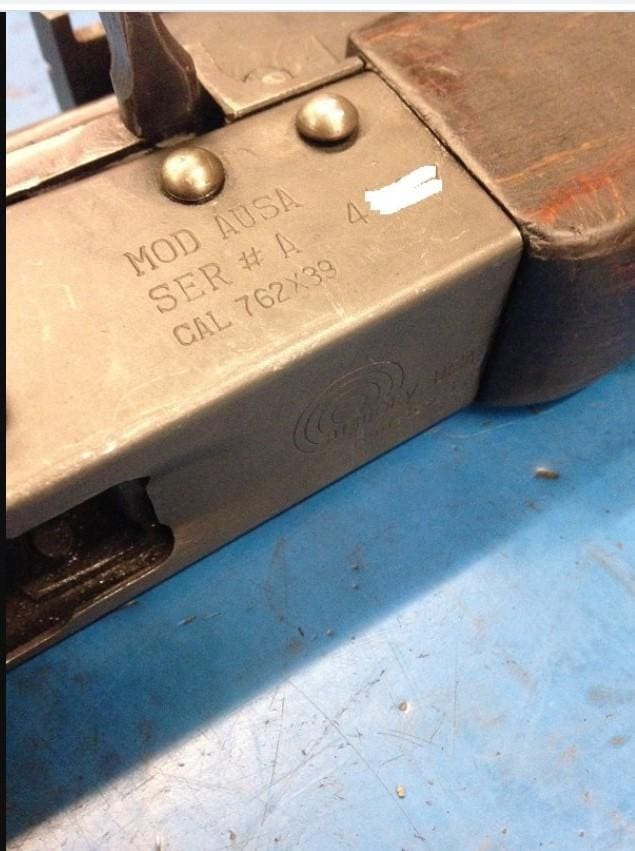

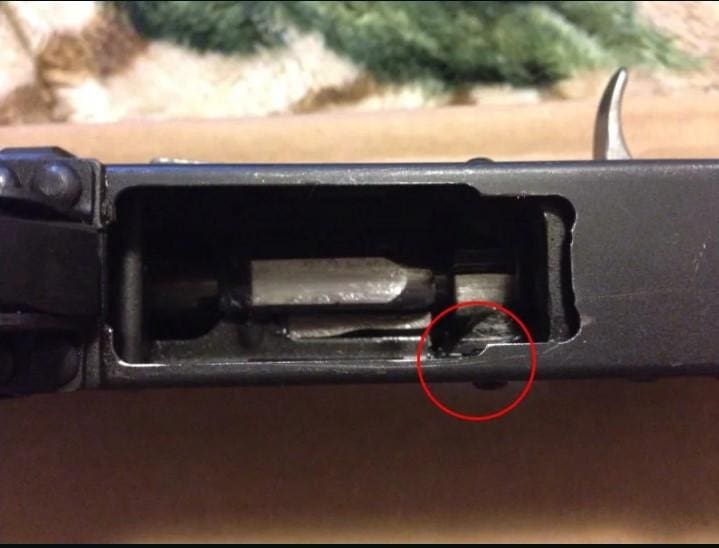

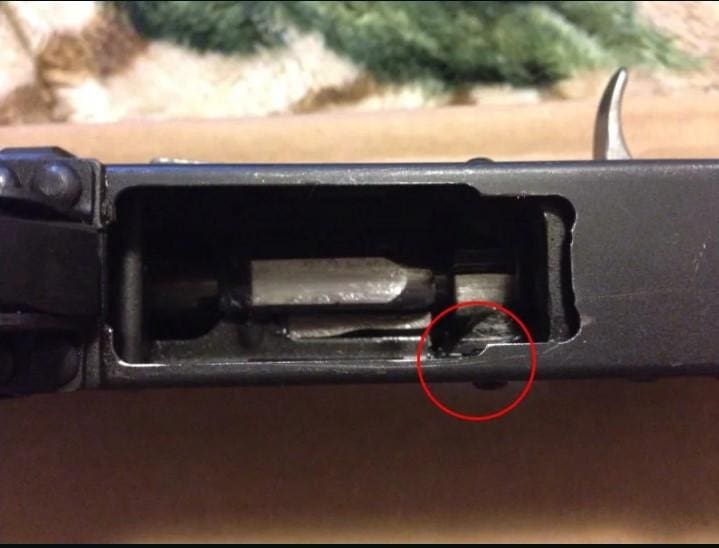

Q: It looks like your WASR is full auto? Can’t tell if that’s the bare Y stamp or there is a third pin there.

A: There all converted to full auto rental guns. Tip of safety sear circled in red.

Q: Hey Ron, I appreciate your stories and input in other threads! You mentioned that the n-paps were cracking much earlier than other guns like WASRs. Do you employ OPAPs also? If so, how did they fare? How long did the NPAPs last before being deadlined? Did the gunsmiths try any mods to make the rifles run better like new recoil springs? There is some question in the Yugo-specific forums around the net about some quality issues prevalent in these rifles. It seems it could be a heat treat issue or an issue like a short recoil spring in these rifles.

A: I posted quite a bit of information regarding our experiences with the N-PAP on the AOUL 47-74’s Facebook page but I can’t seem to find it. We only used the NPAPs on the range and they failed miserably in a short amount of time. It appears, in my opinion, that the receivers were not heat-treated correctly and they cracked. The receiver cracked vertically between the trunion and center bushing.

I had one of my staff with me when I was posting on the Facebook post and he was helping me remember all the issues we had with them. We actually rewelded the first one and thought it was a fluke but another receiver soon cracked and they found a stress crack upon further inspection of another. We destroyed the receivers (and removed them from the NFA Registry) and sold them off as parts kits. They were good-looking rifles but not worth the liability of keeping them on the line.

Here’s a pic that demonstrates where we initially welded the receiver. I thought it was just a hot round that caused it to crack. There were no signs of overpressure or burning on the bolt, carrier, or trunion area but after running the range for the last two and half years, nothing will surprise you. We used the plasma cutter to demil the weapon before removing it from the NFA registry.

After the other NPAPs had issues we pulled them all. I am in no way saying that all Serbian weapons are prone to this or the older Yugos are of the same quality. I just know what happened to our rifles and we can’t risk the liability of a catastrophic failure on the range. I know Century imports them and doesn’t cast any fault on them either because all of the WASR’s we get from them have all been home runs.

If any of you guys are ever in Vegas and want to see the backside of the operation here at Battlefield Vegas, email me at [email protected]. We’ve brought back many Arfcommers for a tour of the back and how we keep this play moving.”

Slightly off-topic but here are pics of three weapon lockers that are filled with issues. It’s not just related to AK’s because the work never ends. We are shooting close 400,000 rounds on the range monthly right now and I don’t think ANY weapon other than our M-134 miniguns were meant to throw that much lead downrange so quickly. We have three M-134’s just to make sure if one goes down, we have a back-up and then another back-up.

You can see a Chinese NDM-86 (Dragunov) that’s on its last leg and there’s nothing we can do about it because parts don’t exist. It will make a nice wall hanger”

Q: How high were the round counts for the Saigas when they failed? Were they 7.62×39? Did they fail sooner than the AKM designs?

A: We haven’t lost a Saiga yet but to be fair, they don’t get run too often. I stated in a previous post about customers that will only shoot a Russian weapon. Most of them are gamers (Xbox, PlayStation, etc) but there are others who are history buffs that just want to shoot a “real Russian AK”.

I did forget that we do have some full-auto VEPR’s that have held up. They are the VEPR-12 shotguns that we post sampled for a specific military demonstration because they couldn’t acquire factory VEPR-12 MGs within the time period they needed. They weren’t the easiest to convert to full-auto but they run flawlessly and we never had to touch the gas system. It runs on almost any ammo except for frangible 00 buckshot.

We only use the factory five-round mags because no matter how much we try to prepare customers for the recoil, they don’t understand until they are off-target and aiming at our baffles. Five rounds will usually get the shooter to the bottom of the overhead baffles downrange. It gives them a good experience with five rounds and we don’t abuse our baffles. The VEPR-12’s get used every day but nothing like a regular AK.

Q: Have you ever tried a recoil buffer? I wonder if they actually work.

A: If your rifle is over-gassed, they do, unless it won’t function with it in, then, they don’t

We have used them but we have no real way to measure their effectiveness. If we would have placed one in two identical weapons at the same time and checked the weapon for wear that would have been a good gauge. Also, they do get chewed up pretty well but is that because that material shouldn’t be in there in the first place?

Q: Thanks For some interesting reading HD, Do you happen to have any Egyptian Maadi’s? I have been curious how they would hold up.

A: We have one factory Maadi on the line and I try to keep it in the vault. It was in mint condition when it arrived but now looks like it’s been through two Arab Springs- V/R Ron

Q: Are you running any AKs with US-made barrels on the line? Would be curious how they hold up at high round counts.

A: We put three of the original milled C39’s on the line when they first came out and they have all been pulled because of the barrels keyhole. We might try some of the new nitride barrels and see how they hold up.

Q: What sort of cleaning/maintenance do you guys do? Frequency, method of cleaning, method of lubrication, etc… curious what works best for extremely high round count guns.

A: Each weapon has its own maintenance log that records the last cleaning, who cleaned it, headspace, and any parts that required replacing. The weapons, depending on the model and volume on the range, are cleaned every 2-7 days. The MP5 SD’s are the dirtiest of the weapons and the M-134 “miniguns” are probably the cleanest.

Because we are a business, we have several things we have to take into consideration. The cleaners and lubricants have to be safe and non-toxic for the employees to handle on a daily basis. Our ultrasonic tank is filled with Simple Green that a waste disposal company has no problem picking up. We were limited to what types of fluids they will dispose of and Simple Green was the best for employee safety and it can be picked and disposed of without concerns. One problem with ultrasonic cleaners (and I don’t know if this is a Simple Green effect) is that copper deposits from barrels will re-deposit themselves on any metal parts that sit too long in the solution. I once pulled out an MG42 top cover that looked like somebody plated it with dull copper because it was left in the tank overnight.

As stated above, depending on the weapon, they get cleaned every 2-7 days. Weapons are inspected every morning and afternoon and that’s also when they are lubed. We use Slip 2000 on all of our weapons. It’s safe, non-toxic, and keeps the weapons running properly. We keep an MSDS log of all the cleaning items within arms reach because of the OSHA and the Health District. They have both done inspections at our range and we haven’t had a problem by following the rules. BTW, we even have to keep MSDS’ on every type of round that we have inventory

I know some folks REALLY think that “their” brand of lubes and cleaners are the best but I can tell you that, in OUR experience, they have all worked about the same. When we first opened the range, we weren’t up to speed on all the issues with OSHA, EPA, and the Health District because we were relatively small. We used what we could afford and we spent more (what I felt was more than we needed) on some of the different lubes and cleaners that everybody raves about. We can’t afford to just keep adding lube to guns and seeing how long it can go without cleaning as so many people do online. We have to maintain our weapons and a dirty weapon doesn’t help with reliability. In fact, my oldest son (who works at our retail gun store) brags about he hasn’t cleaned his M4 in over a year because the lube works so well. There’s a reason he doesn’t work at the range or maintain any of our weapons. He reads BS online and our range is far from a kid shooting 300-400 rounds once a month or so.

We’ve had plenty of rep’s stop by and provide us with free samples and provide demonstrations (one even licked their product to show us it was “safe”) but at the end of the day, it’s about what works, how easy is it to dispose of and will OSHA or EPA have any issues with it.

BTW, I do suffer from a bit of dyslexia, and sometimes when I’m typing, words and sentences look correct, even after proofreading so if you see an edit, it’s because I probably noticed a typo after the 7th time of reading it.

Q: I’ve always heard Simple Green and aluminum parts were bad jujus. We have a couple of ultrasonic cleaners at our shop (we do Cerakote on small and OEM levels) and we’ve stayed away from Simple green for that reason. I’m assuming you’ve had no issues with it?

A: We heard the same thing but from what I remember about our conversations, it was when the acidity level in the Simple Green started to rise is when it was supposed to be detrimental to aluminum. We ran test strips in our solution for probably the first 4 weeks and the acidity never really moved. At that point, they changed our fluid and it’s never been a problem for us.

Q: OP, how often have you had an AK firing pin fail?

A: We’ve lost, at most, 3-4 firing pins in the last few years in our AKs. The one weapon that gobbled up firing pins was the NDM-86 .308 Dragunov. We started making our own firing pins because they aren’t available. We switched over to a Russian 7.62×54 Tigr SVD and we haven’t had any issues.

Q: What happened to the Chinese Dragunov? I’m very interested in the durability of these rifles and I know that some have gotten damaged by out of battery detonations when using the wrong primers. But I’m curious if any problems come up with general use that is not ammo-related.

A: The headspace got so excessive that it was shearing the cases. When the armorers were telling me that the headspace was getting excessive I honestly thought they weren’t checking it properly. Soon after they told me I was in the armory when an RSO brought it back with a stuck case. We pulled the broken case, gave him the rifle, and let him finish up with his customer. After he finished, I retrieved the rifle from the line and checked the headspace myself. Sure enough, they were right and it swallowed the field gauge with ease.

I was more surprised than pissed. I’ve always liked Chinese AK’s and the NDM-86’s look so damn sexy but the weapon was on the line for all of two years and the headspace went to crap. It usually got daily but nowhere near the number of rounds any of the AKs, AR’s or even factory East German AK .22’s go through. Right now it’s just sitting in the lock but I’ve purchased two Russian SVD Tigr’s as replacements and we haven’t had any issues since.

Q: Kinda bummed after reading this thread. I recently bought an NPAP and thought it was the shit. Can you provide approx round can’t in which they ‘died’?

A: Don’t be too bummed because this happened to be our experience with what I am going to assume is a certain batch of rifles. These rifles are subject to extreme abuse and some days we have an hour and half wait ALL DAY LONG and we are open from 8:30am to 7:30pm.

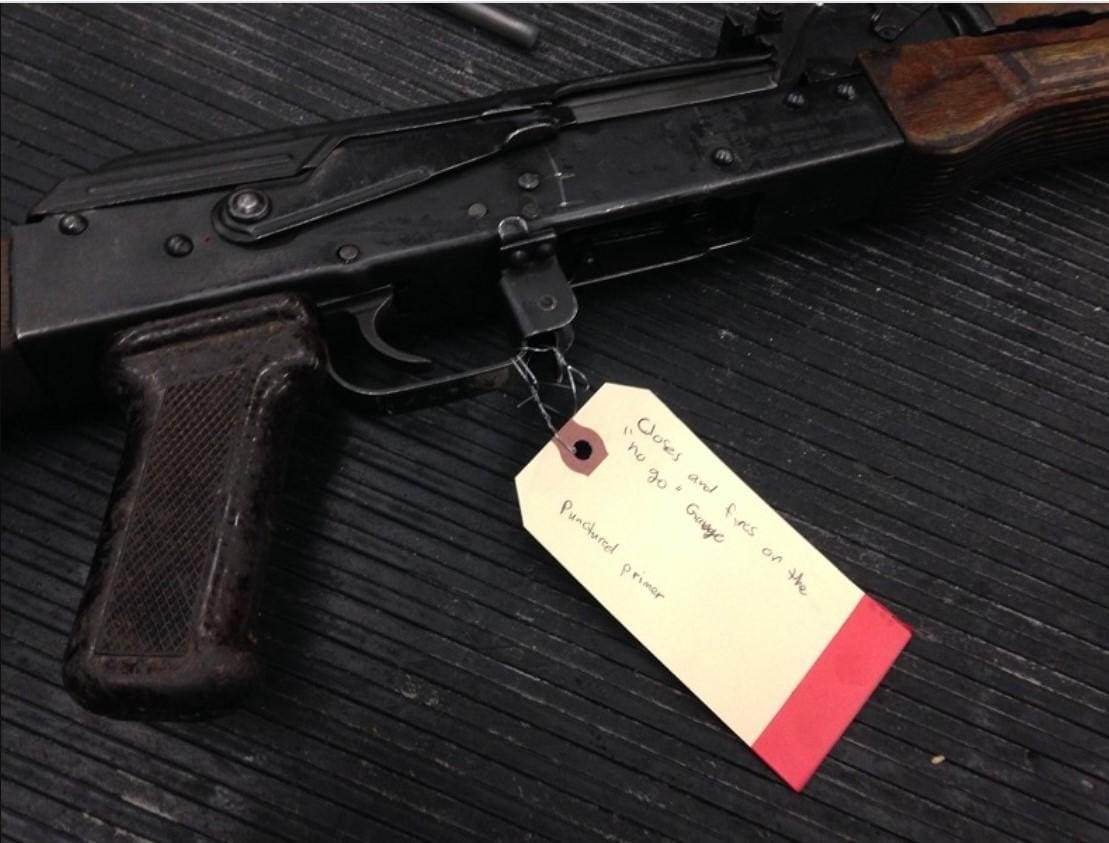

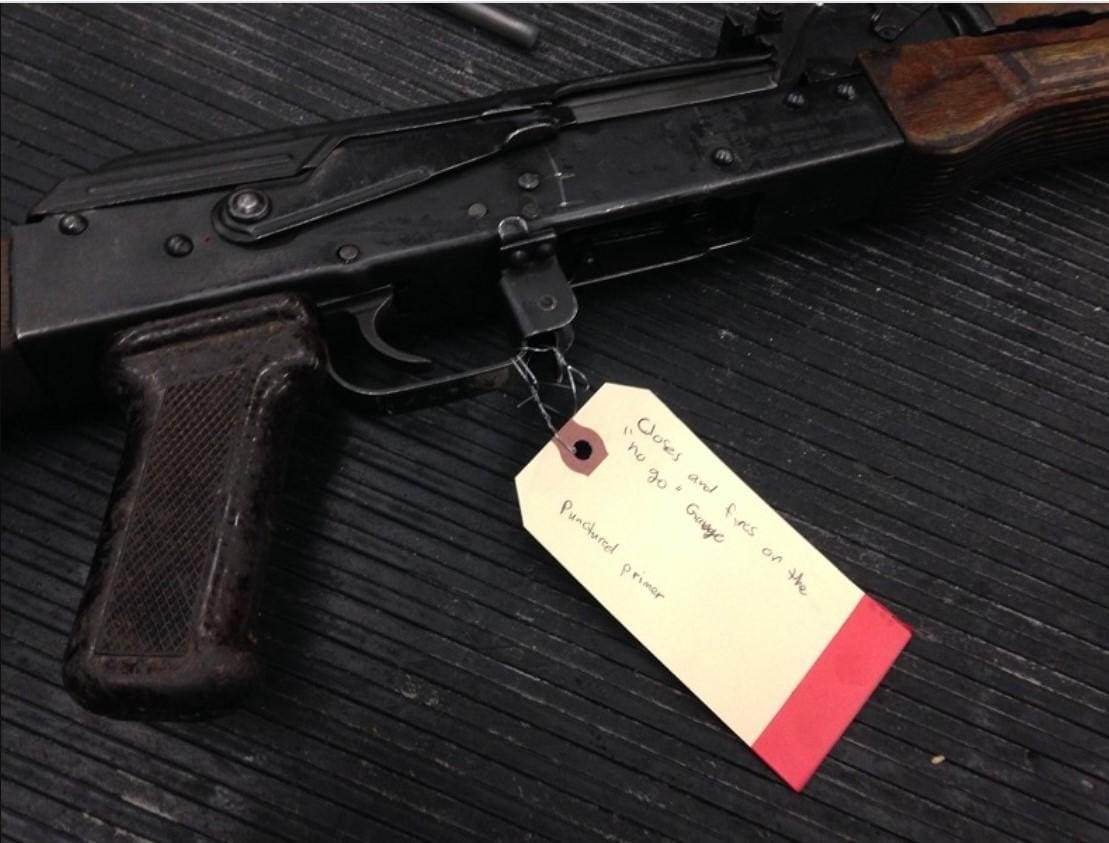

This WASR was put on the line back on 16 OCT 12 and the last cleaning was 21 MAY 15. One of the RSO’s noticed that a primer was punctured so he took the weapon off the line for an inspection. The RSO grabbed the “no go” gauge and when it closed on it, he tagged the weapon for the armorer. The armorer ran a “field” headspace gauge through it and it swallowed it no problem. The maintenance log shows that it had a headspace issue last September and that a new bolt was installed and brought back into spec. This weapon easily has 100,000 rounds through it and the barrel still does not keyhole but the headspace could not be brought back into spec with any of the bolts (we have a bin of 20+ new bolts). The best we could get out of a new bolt was not closing on a “no go” gauge. This weapon has a detailed history and other than the bolt replacement, it received a new furniture set in JUL 13.

This WASR was put on the line back on 16 OCT 12 and the last cleaning was 21 MAY 15. One of the RSO’s noticed that a primer was punctured so he took the weapon off the line for an inspection. The RSO grabbed the “no go” gauge and when it closed on it, he tagged the weapon for the armorer. The armorer ran a “field” headspace gauge through it and it swallowed it no problem. The maintenance log shows that it had a headspace issue last September and that a new bolt was installed and brought back into spec. This weapon easily has 100,000 rounds through it and the barrel still does not keyhole but the headspace could not be brought back into spec with any of the bolts (we have a bin of 20+ new bolts). The best we could get out of a new bolt was not closing on a “no go” gauge. This weapon has a detailed history and other than the bolt replacement, it received a new furniture set in JUL 13.

So today it’s coming off the line until we install a new barrel.

Here’s where we are at with a standard WASR after two and half years on the line…

– The trunion and the receiver show no signs of wear or fatigue at this point.

– No stress cracks can be seen on the upper rails or at the rivets.

– Bullets do not keyhole

Q: One question on the WASR, how does the ejector look?

A: I will get some pictures for you tomorrow. I can tell you that we’ve never had an ejector crack or wear down from use.

OK… here’s something for all the guys with home-built guns. I built this gun probably 5-6 years ago, if not longer.

V/R Ron Battlefield vegas

Here’s a little backstory about it. This gun was used for Foreign Weapons Training that we were subcontractors for at Ft Polk. We were flying out of town twice monthly and needed an additional thirty AKs for training. We were training military personnel with AKs, PKMs, RPKs, RPDs, and SVDs and for some reason couldn’t get any other AKs at the time (can’t remember why).

This kit was not built the way almost everybody else builds them. The rivet holes were not dimpled, swell neck rivets weren’t used and the cheap Hansen “bag of rivets for $3” was used with the exception of the rear trunion long rivets. I had to use the rivet trimmer for all the Hansen rivets and used one of the rivets crushing jigs with the crushing arm that’s used with a press. The rear rivet crusher was an even simpler design (can’t remember the mfg?) that used a large piece of square tube that you set the receiver in and on top of the backing plate. The top had a modified machine bolt that was also used with a press to crush the rivet. The two long rivets were factory Bulgarian rivets that I purchased from K-Var/Arsenal.

This rifle was pulled off the line today because the RSO couldn’t keep the top cover from falling off. He brought it to the armorer who right away tagged the weapon. He initially thought it was a broken rear trunion (he only scanned over it while working on the M-134 minigun) but I happened to be in the back and noticed that it wasn’t a broken trunion but the rivet heads were shearing and actually cracked a portion of the receiver. The weapon has had a bolt and a slant brake replaced. Other than those two issues, the weapon has been unremarkable. Headspace is still within spec and no issues with putting rounds in the center of the target. The six trunion rivets are still seated flat against the receiver with no evidence of shearing visualized. The five trigger guard rivets are also unremarkable. BTW, the serial number is below 4,100.

This is another weapon that has been part of the inventory even before opening the range. It would be fair to say this weapon had approximately 10,000 rounds through it prior to range duty and by judging from the maintenance log, we put an additional 60,000-70,000 rounds through it. We’ve had factory AK’s lose rivets to include one WASR, several Century M70AB72T’s, and a Norinco MAK-90 but they all were lost at the front trunion. This is the first AK to have an issue with the rear trunnion.

This is another AK that has been on the line since we opened and used for FWT at Ft Polk prior to that. Some of you guys have inquired about ejector wear and you can clearly see that the ejector is still very much in spec.

Here is an example of a broken upper rail that occurred yesterday. The shooter was on the line and the weapon malfunctioned halfway through a magazine. The RSO noticed the bolt lifting up on one side after the top cover popped off. He grabbed a new AK from the rack and when he finished up with the customer, brought this AK back to the armorers.

It seems we have a pattern for stamped receivers to fail along the top rail. Here’s another WASR that cracked yesterday and initially the RSO that it was a kaboom but when I inspected it, it was clearly a cracked rail. When it cracked, it kept the bolt in the rearward position but the trunnion and bolt were intact.

This AK went on the line in December 2012 and other than a change of furniture and a new bolt installed, records reflect an unremarkable history. This compares to the other AKs that suffered from the same failure and that was around the two-year mark.

Q: So this seems like the AK IS pretty indestructible. I mean, there are armies who aren’t going to put this much lead through a gun. Not to mention I’m guessing these get full auto mag dumps? I’m guessing the average joe’s AK will last several family generations even if it sees multiple SHTF scenarios.

A: Here’s something that we’ve never seen before. This weapon was first cleaned on 28 OCT 12 and it’s fair to say at that time, it could have gone for at least 10-14 days without cleaning because we had only been open less than four weeks. It was used prior to that for foreign weapons familiarization courses at Ft Polk but the Army didn’t like full-auto use. They wanted the soldiers to understand the weapon system as to take-down and fundamentals. Each soldier got two magazines and only halfway through the second magazine were they allowed to switch the selector lever to full-auto and burst it. They were never abused.

That being said, this weapon easily has 100,000+ rounds through it and so far, it still has the original bolt and barrel. The headspace continues to remain within spec’ and the receiver shows no signs of cracking, wear, or fatigue.

We’ve had AR/M4 gas tubes erode away to the point where they just float around in the handguards (or just fall out of the railed handguards) and I thought that was another weak point of the M4 versus the AK. The AKs have continued to run and even the Chinese and early Bulgarian (maybe they still do, not sure) have gas vent holes in the gas tube so I am pretty confident that it would have continued to run. In fact, this weapon was still running perfectly prior to cleaning when one of my RSO who was assisting with maintenance noticed it (good catch Doug!).

Q: Thank you for all your wonderful posts. I’ve found 3 thus far: the AK thread, the handgun thread, and the AR thread. Are there any other threads I haven’t found? Do you have any IMI Galil info you’d like to share?

A: The one thing we’ve lost on our Galil’s as compared to AK’s (both 7.62 and 5.56) are firing pins. I don’t know why but we’ve replaced 3-4 firing pins (instances that I can think of) since we’ve opened. Galil’s get used daily but maybe 5-6 times a day max for the most part.

Q: How are the SIG 550, 551, and 553’s holding up? What parts are you seeing fail on them if any? I have a SIG 553 that I SBR’d and I am buying spare parts. I don’t imagine my volume of fire will come close to what your rifle’s experience, but it never hurts to be prepared for a possible failure.

A: The only issue we’ve had with this platform is the recoil spring breaking. We’ve had two go down (we only have three) since we’ve opened and it was just the recoil springs that needed replacing.

Q: Ron! First, thanks a million for the info! We owe you! So your milled AKs don’t suffer the same failures as stamped and last longer between failures is that correct?

A: Yes sir. We have yet to lose a milled receiver.

Some Insightful Q&A Between Forum Members:

Q: I have read the entire thread at least once since the mag well is the receiver and the bolt is in the receiver, out of curiosity how do you know? I thought the OP might say more about it. I know he said they were cut up and sold without taking pics.

A: Well obviously I wasn’t there so I can’t say that I know. However, I’ve built/repaired more than enough of them to have an idea. They posted this picture showing where they would weld the receiver in anticipation of a crack forming:

So given that’s the area of failure, let’s look at the options. First, the single stack bolt. What makes a single stack bolt different from a double-stack? Well, the lower extrusion of the bolt that contacts the rounds in the magazine is lower than its double-stack counterpart. All other parts of the bolt are the same dimensions, including the bolt lugs, which are the only real parts that continually contact the receiver. So if the failures aren’t being observed in other double-stack bolts, 1mm receiver guns, then it’s safe to conclude it’s not the contributing factor.

Left is a single stack, right is the double stack:

The second is the mag well at the point where the weld is made is at the point just before the mag well gets “thicker” as it transitions into where the beak of the mag is inserted. This area, though, is typically the same or thicker than a WASR, which also has its mag well opened up by Century. As has already been stated by Henderson, the WASR has been their golden child. So if the failure isn’t observed on the WASR which has the same procedure and overall dimensions of the NPAP, then it’s safe to conclude that it’s not the issue.

Top is NPAP, bottom is WASR:

What could be the problem? In an AKM/earlier pattern AK, the bolt carrier contacts the right side of the trunnion when it reaches its forward most travel. Since the right side contact point of the trunnion is located well within an area where the receiver is solid, the forces being generated on the trunnion as a whole are causing more stress on the left side of the trunnion where the receiver is cut for the mag well.

Now, as we stated previously if this failure point isn’t observed in the WASR which follows the same principle, why is the Yugo failing? Could it be that the reports of Yugo rifles not being properly heat treated are the cause? Possibly. I wouldn’t make that claim without testing one, but at this point, it would seem plausible.

Point where bolt carrier contacts front trunnion and its approximate location in relation to the receiver (same for WASR and NPAP):

Back to the AK-47 Abuse thread!

Q: In most AKs I’ve seen, the bolt carrier rarely contacts the trunnion on the right side, but instead on the left on the large shoulder of the locking lug. The AK-74 even has an angular surface here versus a flat surface on AK/AKM – not sure what the purpose is but someone revised the contact surface.

I’m in China right now so I can’t look but I recall my M92 having an indent in the receiver in the location of Henderson’s crack. It’s possible that Zastava is doing something weird when bending the receiver into shape, as the indent looks like what you typically find on rails and such as an indication of where they were pressed in a sheet metal bender.

A: All AKs prior to the AK-74 should have the bolt carrier contacting the right side of the front trunnion as this is how it was designed. There should be a gap between the bolt carrier and the left side of the front trunnion. This was changed with the AK-74 to contact the left side and, as you stated, they added the angular contact point. Every example of pre-74 AK that I have contacts on the right and every post-74 AK contacts on the left.

Back to Ron With Battlefield Vegas!

Here is a Century M74 Sporter that was first put on the line back on 10 NOV 12. This rifle has an extensive cleaning list with zero parts replacement. The headspace has remained within spec after all this time and it’s a US-made barrel. I don’t know who Century subcontracted these out to but it certainly served it’s purpose until it started keyholing.

Q: About how many rounds before it started keyholing?

A: I haven’t had a chance to review all the maintenance records on that rifle but considering the day it was put into service, a VERY conservative number would be no less than 50,000 rounds.

Q: Are you going to re-barrel it?

A: More than likely we will but not anytime soon. The receiver still looks perfect so I will have to purchase a new 5.45 bolt along with the barrel when the time comes.

Q: What are the issues you’ve experienced with the RPDs? I’ve built a couple of posties(sadly now sold) but never put more than 10k rounds through one. Very curious if they were rewelds or commercial receivers.

A: We have used both rewelds and Vector/DSA receivers on the line. One thing they all do is start to crack at the rear half of the receiver near the take-down pin. All of the receivers fail in the exact same manner and wouldn’t say one is better/worse than the other. I can’t remember which parts specifically but I know that we’ve had a couple of top covers go down from parts coming loose.

On the last two DSA receivers that went on the line, we actually welded some saddle plates over the take-down holes and made longer take-down pins. They haven’t suffered from any cracks as of yet and they’ve been on the range since early February IIRC.

A little tip for you guys that own either a post sample or semi-auto RPD.

V/R Ron

If you didn’t receive one of the tobacco-style blued cleaning kits, purchase one. Your weapon shouldn’t have a problem running on the first gas setting and it will help extend the life of the receiver by not beating it up. If the weapon starts malfunctioning, most people will want to increase the gas flow and put the setting on the second or third setting. After extended use, the gas ports on both the barrel and the gas cylinder will foul up. The cleaning kits come with a port scraping tool that fits perfectly into both the barrel and the gas cylinder and unlike a drill bit, screwdriver, or other sharp objects, you’re not going to remove any material and speed up the erosion process. It also has a wrench that is the correct metric size to remove the gas setting plug without any chance of stripping it because it grabs it on all corners.

Q: So, if I have read this thread correctly, what I have learned is:

Milled receivers outlast stamp.

Stamped receivers will suffer cracked trunion at 80,000-100,000 rounds

Bolts will last to about 80,000 rounds.

The gas tube will erode in 100,000+ rounds

US barrels (74’s) will last for around 50,000 rounds.

Simple Green is safe to use for cleaning.

AK’s last longer than RPD’s

WASR is badass!!

Right?

A: Pretty good summary. I will have some more pics of a bolt that suffered some major erosion and the weapon was only on the line for slightly under three months. The hot gas eroded a hole clean through the stem of the bolt.

Here’s an example of one WASR that didn’t last as long as others. This is not the norm but with all of our past good experiences with WASR’s, this is definitely worth noting.

A little background on this exact WASR. It went on the line 09 JUN 15 and has been used every day since with the exception of routine weekly cleaning. It was never off the line for a whole day, just cleaned and put back in service. This WASR did see quite a bit of use because of the new blonde furniture and RSO’s usually grab the cleanest and “prettiest” weapons as previously discussed. The weapon did NOT have any function or reliability issues, it was just brought for cleaning when all of these issues were identified. The first thing that my armorer noticed was the erosion in the bolt. After seeing that, they figured there had to be other issues so they took their time and checked further for other issues. That’s when they noticed the erosion through the gas tube and the crack in the rear trunnion. Again, this weapon continued to function properly but it had to be pulled at that point because of safety issues.

As for round count, AK’s, Uzi’s, and AR15’s get the most use but because of the “double your ammo” special with the AK, they get run even more. I can say a fair estimate for this weapon is 30 times in a day with magazines loaded to 25 rounds.

If you take that number and consider it was on the line for 3 months, then a fair round count is 60,000+ plus rounds during that time period.

Before anybody starts knocking the quality of the WASR’s, this is the first time we’ve seen such wear on a fairly low-round (in our experience) WASR to date. The headspace is still within spec and there are no signs of wear or fatigue on the bolt or trunion. The rounds are still hitting the center of the target accurately (at 10-15 yards) and not keyholing.

V/R -Ron

Q: I take it you find it easier to rock in a magazine that’s downloaded? Or more reliable feeding? Or do the magazine springs last longer? Any other mags you find downloading helpful in?

A: We load 25 rounds to make things easier on our accounting. The ammo comes packed in 1,000 round cases and it’s easier to “GI proof” the loading and accounting situation with an easy number of 25. We know that we can get 40 loaded magazines out of a case of ammo with zero extra rounds floating around in comparison to 33.3 magazines loaded with 30 rounds per magazine.

Ron V/R Post:

This AK was put on the line less than two months ago. The date was 11 OCT 15 to be exact and we already suffered a cracked rail. This is very unusual for any of the WASR-series of AK’s to experience this kind of failure at such a low round count. This is a good example of things that are way out of the norm but when it happens some people online will right away say “my WASR only lasted 15,000 rounds and it cracked.. it’s a POS”.

I know from our experience that isn’t the case but every product made is going to have a sample that for one reason or another fails. We will be able to weld that rail back in place and hopefully, that’s the end of issues but we will definitely keep an eye on the other rail during each cleaning to inspect for any stress cracks that are forming.

Q: Any word on the C39’s with headspace issues? Did pressing the barrels further in and re-pinning them fix the problem?

A: It did fix the problem and if you know how fractional an amount of distance is involved in the headspace, it worked. An over-size barrel pin was used (after the original hole was opened up slightly).

BTW, just to clarify which milled rifle had the headspace issue. I didn’t go back re-read my posts but I believe I called it a C39 thinking that all of Century’s milled AK’s were C39’s. This particular rifle was one of the very first Polish Model 1960 rifles to be sold. I know there is a difference between the Polish 1960 in comparison to the C39 that was my fault if I called it a C39.

Q: Any word on the C39’s with headspace issues? Did pressing the barrels further in and re-pinning them fix the problem?

A: It did fix the problem and if you know how fractional an amount of distance is involved in the headspace, it worked. An over-size barrel pin was used (after the original hole was opened up slightly).

BTW, just to clarify which milled rifle had the headspace issue. I didn’t go back re-read my posts but I believe I called it a C39 thinking that all of Century’s milled AK’s were C39’s. This particular rifle was one of the very first Polish Model 1960 rifles to be sold. I know there is a difference between the Polish 1960 in comparison to the C39 that was my fault if I called it a C39.

Q: Anything new?

A: The only thing that we’ve seen recently that was out of the ordinary (from our regular experiences) is a gas tube that had a huge hole blown through the side of it. The weapon continued to run properly and nobody complained of hot gas bothering their hands or fingers and was only discovered after it was disassembled for cleaning.

I believe we at least 30+ AK’s that are all off the line due to cracked stamped receivers or barrels that keyhole. We will probably just deadline those AK’s into dummy guns at this point. We have dummy’ed several of them with welded up chambers, welded over firing pin holes, firing pins removed and the magazine follower welded to the body. There is no way they can chamber a round or even pick up a round at this point.

Q: I’m sorry if you’ve already stated this, and I have searched, but what brand of ammo and flavor do you run in the 7.62 AKs? I’m assuming you guys run the type with the least amount of issues.

A: We are only using Wolf in our AK’s. It’s the 122/123 FMJ grey steel case ammo.

Update Commentary by Ron:

Well, I guess the only thing left to break would be a barrel because we’ve experienced broken bolts, stocks receivers and both front and rear trunnions. The lower portion of the carrier that keeps the bolt in place cracked from the main body earlier today. This is a Bulgarian-made 5.56mm “Krinkov” imported by Arsenal, Inc here in Las Vegas.

I will get records of the date is came on the line but it’s at the very least 12 months old. This weapon doesn’t have any other issues or malfunction listed on the maintenance log and has been unremarkable up to this point. The strange thing about this break is that the we don’t actually know when it broke other than when it was cleaned four days ago, there was no evidence of a fracture or crack in that area.

The weapon didn’t come off the line because of a malfunction but rather for a weekly cleaning and inspection. The durability of the AK is pretty amazing considering this weapon suffered a catastrophic failure of the carrier and continued to function until it was disassembled for cleaning. One would expect the weapon to have functioning issues if the portion of the carrier that is used to push rounds from the magazine and into the chamber was completely cracked. V/R Ron

Q: Posted this in the other thread, but cross-posted here. I know you had C39 issues, but I thought I read you bought some C39V2s, and supposedly, those have addressed the issues that the other C39 had.

A: The round count of the C39V2 is still very low in comparison to a standard WASR or the original Polish Model 1960 (Century’s first milled gun on Polish kits). It doesn’t get used much because people tend to choose the classic wood-dressed AK47.

Q: As a purchase for a guy that’ll shoot 2,000-3,000 a year, how would you rate it?

A: I would definitely put this on a list of go-to AK’s

Q: Ron, have you ever used buffers on AK’s and what was your experience with them?

A: We have, we’ve used the black ones and the blue ones. I’m falling asleep as I’m typing this and can’t remember the brands for the life of me but I do have the armorers install them.

Q: any SLR-107’s (AK-103) on the line? How are the Draco’s holding up?

A: We do have a few of the SLR-107’s and they have held up just as well as the WASR-10/63’s? As for the Draco’s, they are still running strong. We’ve lost a few to cracked rails but we have tigged them back in place and continue to run.

Q: Any Mini-Dracos?

A: We have one that we call the Flamethrower but it doesn’t get much use. There’s no stock on it and my staff only allows certain individuals to use it. If you’ve never fired a gun, there about 99.99% chance you aren’t firing the Flamethrower.

Q: Last year you posted about critical NPAP failures where receivers were splitting and you dropped them all from the line and got rid of them. In a recent video interview with one of your armorers, he was talking about how you replace furniture on Npaps because the wood stock breaks quickly. Can we assume you’re back to using NPAPs and aren’t having the receiver issues you had last year?

A: I noticed that as well. He meant to say WASR’s. We haven’t put any NPAP’s back on the line because we haven’t had to at this point. We still have 20+ WASR’s new in the box but if they corrected the problem, I don’t have a problem putting them on the line. Sean was a bit nervous because he didn’t know he was going to be doing the video interview and all of the videos that we have posted on our Youtube page.. have PLENTY of take-outs because of that.

Q: In your opinion, which would be a better firearm? WASR or Norinco MAK 90 (pre-banned)? To me, it seems that the Norinco is just a heavier more nicely finished variant and the WASR is bare-bones, not too pretty, but tough as nails. Which one would you trust more on the firing line?

A: Funny you should bring this up. We’ve had WASR’s go the full 100,000 round count without losing trunion rivets but we’ve had two Norinco’s lose their rivets. At the same time, we haven’t lost any Norinco’s to cracked receivers.

Q: Any chance you guys have fielded some of the newer VEPR rifles from FIME/MSR? After reading how well your VEPR-12’s were holding up, I’m curious to know if they’re still doing well, and if you’ve decided to acquire some of their “rifle brethren” or not.

A: We don’t have any of the VEPR rifles on the line but we do have a Saiga 7.62×39 conversion for customers who HAVE to shoot a real Russian weapon. As for the VEPR-12’s not one single failure since they’ve been put on the line.

Thread Update from Ron:

I haven’t updated this thread with any new info lately but I was talking to the armorers about the 9mm AK’s we got from Atlantic Arms. Those things are still running strong with no broken parts and zero issues. We’ve had two of them on the line (both running suppressed) for a little over/under 12 months and they are running flawlessly. It’s a GREAT weapon for females or younger kids that just don’t have the size and weight to handle a 7.62×39 AK variant properly in our range.

On another note, we are going to test a couple of different AKs on the range. Since this thread was started in order to help the average shooter on what works and what doesn’t work, we are going to build several AKs from flats. Some receivers will get the “homemade” type of heat treating and others will get proper heat treating from a facility that specializes in it. I want to do some hard testing and see how well they hold up to a factory WASR or Arsenal. We will be using both chrome-line and nitride barrels and see if we notice any difference. V/R Ron

Q: If it wasn’t for the safety of his customers I would want to know how an IO would do?

A: I believe I made mention and I’m not sure what the relationship between IO and Pioneer Arms is but those AK’s did not last. Trunnions cracked within days and other catastrophic failures. We took them off the line, welded the inside of the receiver up, punched the barrel, destroyed the bolt face, then welded them all back together to use as a display gun for customers.

Member weighs in: Pioneer Arms were made in Poland and contracted by IO. They used the same build practices and, as far as I know, parts as IO does. IO was trying to capitalize on the “Radom” name by fooling people into thinking the rifles came from the FB Radom plant, when in fact they were just in the same town.

Q: Honestly one of the best threads probably on the internet. Thanks for keeping us update and informed along the way with so much information. Just had two questions, since I rolled the dice on a C93v2 not too long ago I was wondering how well they are holding up since hopefully the round count should be up? I didn’t see any updates with exploded rifles so thinking they are still chugging along just fine and also I was curious about your Krinks and how they are doing specifically if you guys had any SLR-104UR’s online, thanks?!

A: The C93V2 doesn’t get as much use as the standard WASR’s but it hasn’t suffered from anything breaking at this point. The carrier still looks decent, no noticeable wear or “egging” of the hammer/trigger pin holes and it’s still shooting “straight”.

Q: Any updates?

A: I am NOW a huge fan of using the buffers inside the receiver! We lost several AKs over the last 2-3 weeks and it’s MY opinion that had we changed recoil springs sooner AND had a buffer inside the action, we wouldn’t have lost that many.

Also.. we are going to put our first AK on the line that was made with an AK-Builder flat and heat-treated with the MAPP gas method. Not trying to destroy anything on purpose, just want to test and research for ourselves if having the whole receiver heat-treated will make a difference under heavy use.

Q: Speaking of, how well are magazines holding up?

A: All of the European mags continue to deliver day after day.

Q: I’m also curious about the 7.62×39 vs 5.45×39 durability and even barrel life even though I’m positive the 5.45 will have a shorter barrel life.

A: I’ll ask the staff but I’m pretty sure the Romanian WASR barrels have outlasted the Arsenal 5.45 “Krinkov” barrels. The armorers recently re-barreled four of the Krinks with the chrome-lined barrels offered by AK-Builder.

Q: You must be busy Ron. Started to miss reading your new inputs. I’m glad for one, the WASR is a good rifle for you. It’s affordable and tough from your information. So I had to order one.

A: We have been slammed and just got busier with one of the indoor ranges closing down last week. WASR’s still lead the pack when it comes to AKs on our range.

Q: Glad I found this thread. Any info about the RPK type rifles and how they hold up? Better than regular AK?

A: The RPK’s don’t get the same amount of use but we have the same 5-6 RPK’s from when we opened almost five years ago. That being said, we’ve used them for upgrade “specials” and they do get some use. Not one issue with the RPK’s to date. We use the Romanian heavy WASR and NOT the light version that Century sold years ago. There’s also one that I built on a NoDak receiver years and years ago that doesn’t have any sign of failure or fatigue.

Q: I am surprised US manufacturers are not lining up in front of BFLV to give their weapons for test fire.

A: We’ve eliminated all of the non-military parts/mfg guns to keep things simple. The US-made stuff that we’ve used just won’t handle the abuse like the Euro and Chinese weapons do. I may still purchase some of the PSA improved AK’s but not until after the first of the year.

Q: Would you care to give us an update on your opinion of recoil buffers? What have you seen that makes you believe they are of any benefit? Also, do you have any 5.56 AKs and how have they been holding up? On par with 5.45 and 7.62?

A: I have no tangible “proof” that they work but if you could see how the buffers look after several weeks, you would have to conclude that they are helping reduce the violent recoil of the carrier. We don’t lose nearly as many AKs as we used to since we made it a policy that all AKs get buffers. The 5.45’s seem to hold up much longer than our 7.62 models.

Q: Any 5.56 AKs (i.e. WASR 3) in rotation?

A: We only used the 5.56 AKs when we had a bad lot of 5.45. We used Arsenal 105 and Krinkov-style guns (I don’t remember their model numbers) and we didn’t have any issues. We stick with the 5.45 because customers who have NEVER touched a gun don’t like the 5.56 because it’s not what’s on the video games.

Special Alert: The first time we’ve ever experienced this. A factory Bulgarian full-auto trigger cracked yesterday.

Q: Anything new this Summer?

A: We pulled all the Draco’s off the line. The front site base/gas block combo with the 90-degree port just collects too much carbon. We experienced six trunion failures with the Hungarian under folders so the rest of them were pulled off the line. They all failed at about 50,000 round count and just to be safe, that’s why pulled them.

We are going to start using some Tortort milled receivers with the parts we pulled from the Hungarian kits. I am hoping we get at least double the life out of the receiver with the milled receiver over a stamped receiver and trunion assembly.

Q: Have you had any Century M70ab2’s with the DCI receivers on the line? If so, what’s your experience been? A random, and slightly off-topic question, but what would you say the estimated round count would be for a standard combloc/surplus steel magazine? Lastly, if you could pick one AK for a SHTF scenario, which would it be?

A: We do have several of the Century M70AB2’s that did their time and then some. After re-barreling two of them twice, I decided to retire them. They were spared the metal chop saw but instead turned into dummy guns for training. I really liked them and almost wish I hadn’t destroyed them but we can’t save them all.

I would say the same 25% of the magazines see about 90% of the use, just by the nature of the range. Mags get loaded, put back in the bin, picked back up, used, and brought back to get loaded and the cycle starts all over again. AK’s mags, Uzi mags, and MP5 mags last the longest on the range. Unfortunately, AUG mags have a pretty short life span on the range.

If I had to pick one AK for a SHTF scenario, it would be a ……………………….. WASR.

Q: Can you try one of the Wolff springs Ak47 XP recoil springs? It’s supposed to be 15% stronger. It manages the recoil a little better than standard springs. I compared both and the Wolff XP spring is like 2 inches longer. That with the recoil buffer is a nice combo, very pleasant to shoot.

A: We do use the Wolff XP recoil springs. Between those and the buffers, we have noticed a definite decrease in cracked receivers.

Q: Hey Ron, I hear ya got a couple of PSA AK’s there now, love to get updates on that when you have time and have some rounds downrange. Thanks!

A: We did receive two of the PSA Gen 3 rifles last week. I will update Palmetto State on their performance on a regular basis and let them make updates. They are not paying us in any way for this “testing” as I would really like to have a source of quality-made AK’s made here in the States.

WASR UPDATE FROM RON:

Here’s something that is about par for the course. This WASR-10 lasted three weeks shy of a full year on the range. The trunion will suffer a catastrophic crack on the right side and about 50% of the time it will also suffer a crack on the left side where the carrier engages it.

The receiver rarely suffers a stress crack on the right from the bulge but strangely experiences a stress crack on the left side where there isn’t a bulge in the receiver.

V/R Ron

Q: Ron, how do the bulgy 7.62 barrels out of the SLR107s hold up to keyholing compared to the WASRs? Also, have you put any of the Zastava AKs currently being imported by the company and not by century back in the line? Also, have you put the new century imported RPK from Romania in the line as well?

A: The Bulgy barrels hold up about the same as the WASR’s. We haven’t put any Zastavas back on the line but I did plan on putting a few back on the line because of the weight. We are still using the older (8+ years ago) Romanian AES-10B RPK’s and none so far have key-holed.

Q: So about that PSAK update…?

A: I apologize for the delay in responding to the PSAK testing. I can’t give you a straight answer because of parts swapping by the staff. We have six full-time armorers and only four of them were working the day we put them on the line. The others had just finished their 4-day work week. I don’t know at what time in the testing did my guys start swapping parts. I figured staff would relay the information the other armorers but it was my fault for not making it clear. On top of that, those armorers didn’t keep the weapons assigned to individual RSO’s for proper round count. They were all over the 8-10,000 round mark before one of the armorers brought it to my attention. I told the staff to keep the weapons secured until I spoke to PSA staff and I just never got a hold of them.

PSA did try reaching out to me quite a few times but at one of the worst possible times of my life. They were trying to reach out to me when my best friend who owned New Frontier Armory was diagnosed with stage four cancer. David, my wife, and I started Battlefield Vegas and I just couldn’t believe what was happening to us. We only got to spend exactly three months from the day I told him he had a dangerous growth in his armpit until the time we sat alongside his wife, parents, and his sister to hold his hand and watch him pass. I didn’t answer very many emails up until that point and let a lot of them just sit unanswered while trying to comprehend what just happened and why it happened so fast. David M Famiglietti left behind a beautiful wife and two amazing kids and those were only things that my family focused on for quite some time.

Fast forward to last week… I put one of my staff in charge of the PSA’s to include their 9mm version. He will be in comms with PSA throughout the process and provide them round count and anything we encounter along the way.

Q: For the last few years WASR’s and the newer AES-10B’s have been shipping with the inferior BASS wood furniture. Some mistake the wood for beech. Basswood has slightly better durability than balsa wood, but not much. It’s garbage.

A: The wood furniture sets on the WASR’s are the first things to go. They don’t hold up on the range and within 2-3 weeks, they have so many dents and gouges from being soft that they make the weapon look “used and abused”. My staff understands my mindset now but initially, they didn’t understand why the big deal about swapping it out. 95% of our customers have never shot a gun, let alone a machinegun. They are already intimidated and scared when walking in and having beat-up and trashy furniture does not help one get over the fear, it makes them wonder if it’s even safe to shoot just by the looks of it. We use Romy G furniture sets are the MUCH better.

Q: Do you guys have any of the new ZPAP M70 Yugos on the line, with the thicker receivers and CL barrels? Was curious whether those stand up better than the old ones you had a fail.

A: Yes, we do have some of the new ZPAP Yugo’s but I wasn’t aware they had chrome-lined barrels. So far so good with them as I haven’t seen any set for demil.

Q: Saw that you mentioned you were running Tortort receivers and just wondered how they seem to be fairing under pressure?

A: We’ve been running 5-6 of the Tortort milled receivers and finally had to pull one from the line. In my opinion, it has nothing to do with the receiver itself but an over-gas issue inherent to all AKs.

Q: A few pages back you mentioned that putting buffer pads and extra-strength recoil springs in the rifles reduced the rate at which the receivers were cracking, and both of these additions would help, to an extent, to counteract the effects of over-gassing. The milled and thicker receivers are able to take more abuse than their 1.0mm counterparts, but ultimately it’s the over-gassing in combination with thinner receivers that are beating the rifles to a pulp after so many rounds.

I’m interested to see how the new ZPAPs handle, given that they have beefier trunnions and receivers that are RPK-spec rather than AKM-spec, I’m guessing they’re going to last a long while. Are your RPKs still ticking?

A: Over-gassing is a HUGE issue for us and we’ve installed KNS adjustable gas pistons on all of our line guns. The KNS pistons reduce the amount of recoil (observed through slow-motion video), reduced the rate of fire and in MY opinion, will help keep our weapons much longer.Over-gassing is a HUGE issues for us and we’ve installed KNS adjustable gas pistons on all of our line guns. The KNS pistons reduce the amount of recoil (observed through slow-motion video), reduced the rate of fire and in MY opinion, will help keep our weapons much longer.

Q: Ron, any broken KNS pistons? The one thing that keeps me from switching over my AKs to the KNS pistons is the unknown factor of the durability of the KNS product.

A: The KNS pistons are a robust design and we haven’t had any issues. Everything eventually breaks but I don’t see a failure point on their design. For the record, we receive no discount and nobody from KNS reached out to us. We just needed a solution for an ongoing problem and hopefully, this is it.

Q1: Not sure if you answered this, but have you seen any cracked 1.5mm receivers like on the Century M70AB1/2 rifles?

Q2: Any experience with the Yugos with thicker 1.5mm receivers like the M70ab2? I always wondered if those are really stronger than the standard stamped 1mm receivers.

A: I’m not sure if we ever posted anything in the past but I was going through our inventory of weapons last week and came across an M70AB1 from Century that had cracked. We also had another Yugo (Century build) that the front trunnion cracked. They lasted a long time on the range and I know some people don’t like Century but I was really impressed with how well it handled.

That’s All Folks!

Well, that’s all we’ve got for you thus far! The last post was made on 7/29/2021 and we’re eager to find out if the PSAK-103 by Palmetto State Armory will become a staple AK for Battlefield Vegas or if will it be better suited for semi-auto fire.

Stay tuned and find out! We will keep you updated as we learn more in the coming months…

Exoctactical would like to send our condolences to Ron for his loss… we’re hoping that Biden’s recent ban on Russian ammo won’t have an irreversible impact on Ron and those employed by Battlefield Los Vegas.

Until next time, soldier on and thank you for stopping by!

I am going to go ahead and bookmark this content for my sis for a coming up study project for school. This is a beautiful web site by the way. Where did you get a hold the theme for this website?

Thank you pertaining to taking turns that excellent subject material on your web-site. I discovered it on the search engines. I will check back again if you post more aricles.